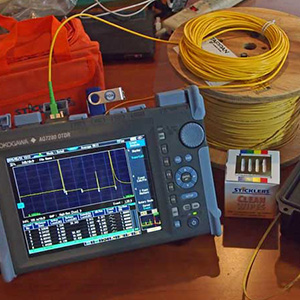

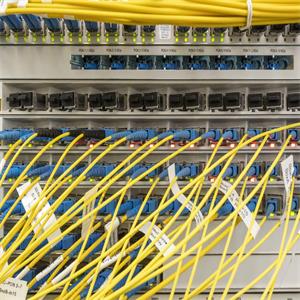

In the realm of fiber optics, having clean and smooth fiber end faces is crucial for low-loss and low-reflectance fiber optic splices or terminations, especially when using pre-polished connectors with internal splices. The fiber cleaver is an essential tool for achieving this, often working in tandem with fusion splicers to produce optimal results. It is the cornerstone of high-quality connectors and splices.

What Is Cleaving and a Fiber Cleaver?

Cleaving is the process of precisely breaking an optical fiber for termination or splicing. Similar to cutting a glass plate, the fiber is scored or scratched on the surface, and then stress is applied to create a smooth break along the stress lines. When done correctly, the fiber will have a clean, perpendicular surface with no protruding glass on either end.

A fiber cleaver is a tool that holds the fiber under low tension, scores the surface at the correct location, and then applies greater tension until the fiber breaks. Good cleavers are automatic and produce consistent results, regardless of the operator. With high-quality fiber cleavers, you simply clamp the fiber into the device, operate the controls, and the fiber is cleaved automatically. However, some less automated cleavers require operators to manually apply force to cut the fiber, making it difficult to predict and control the force. These are known as precision cleavers and scribe cleavers, respectively, and we will delve into them next.

Two Types of Fiber Optic Cleavers

As previously mentioned, fiber optic cleavers can be categorized into precision cleavers and scribe cleavers.

Scribe Cleavers

The scribe or manual cleaver, which is cheaper than the precision cleaver, is the most original type of fiber optic cleaver. Scribe cleavers typically resemble ballpoint pens with diamond-tipped wedges or come in the form of tile squares. They have a hard, sharp tip, usually made of carbide or diamond, to manually scratch the fiber. The operator then pulls the fiber to break it. Since the breaking process is manually controlled, it is challenging to control the force accurately, resulting in less precise cleaving. This is why most technicians prefer not to use these cheaper cleavers.

Precision Cleavers

As the name suggests, precision cleavers offer more accurate cleaving compared to scribe cleavers. A precision cleaver uses a diamond or tungsten wheel/blade to nick the fiber, and then tension is applied to create the cleaved end face. The advantage of precision cleavers is their ability to produce consistent results through thousands of cleaves by simply rotating the wheel/blade. Although more expensive than scribe cleavers, precision cleavers can cut multiple fibers with increased speed, efficiency, and accuracy. With the growing popularity of fusion splicers, precision cleavers have been developed to support various splicing tasks. They are ideal for fusion splicing standard 125/250um and 125/900um fibers and preparing fibers for pre-polished connectors.

Introducing the ME-2030 One Step Fiber Cleaver

The ME-2030 One Step Fiber Cleaver is a state-of-the-art precision cleaver designed to simplify the fiber cleaving process while delivering exceptional performance. This innovative device combines advanced technology with user-friendly features to ensure consistent, high-quality cleaves every time. The ME-2030 is equipped with an automatic anvil drop mechanism, which reduces the number of steps required and enhances cleaving consistency. Its automated design minimizes human error and the subpar cleaves often associated with manual cleavers.

Key Features of the ME-2030 One Step Fiber Cleaver

- Automatic Anvil Drop: This feature ensures fewer steps and better cleaving consistency, saving time and effort.

- User-Friendly Interface: The ME-2030 is designed with ease of use in mind, making it accessible to both novice and experienced technicians.

- High Precision: The device consistently produces clean, perpendicular fiber ends, crucial for low-loss splices and terminations.

- Versatility: Suitable for a wide range of applications, including fusion splicing and preparing fibers for pre-polished connectors.

How to Use a Fiber Cleaver

To achieve perfect fiber cleaves, follow these steps:

- Open the Body Cover: Place the stripped fiber on the V-groove.

- Close the Holder Cover: Ensure the fiber is securely in place.

- Close the Cover and Move the Slider Forward: This action will cleave the fiber.

- Open the Cover and Check the Cleaved Fiber: Ensure the cleave is clean and perpendicular.

- Open the Holder Cover and Remove the Cleaved Fiber: Carefully take out the fiber.

- Remove the Cleaved Fiber Chip: Use a pair of tweezers to remove any fiber chips.

Tips on Choosing Fiber Cleavers

- Match Your Application Requirements: Determine whether you need a single-fiber or multi-fiber cleaver based on your specific tasks. For fusion splicing, select a cleaver with a low average angle (one degree or less), while for mechanical connectors, angles below three degrees are suitable.

- Consider Built-in Cleavers: If you are considering a cleaver integrated into a splicer, ensure it is easy to maintain. Losing a valuable tool can delay your work.

- Invest in Automation: Choose a cleaver with the latest automation features, such as automated fiber scrap collection, scoring mechanisms, and automatic blade rotation technology. These features can save significant time and labor.

Conclusion

Precise cleaving is essential for successful fusion splicing. The quality of your fiber cleaver directly impacts the quality of your fiber optic splices and terminations. Imperfectly cleaved fiber ends can lead to signal transmission issues. To ensure reliability and precision, consider the ME-2030 One Step Fiber Cleaver. For more information and to purchase high-quality fiber cleavers, visit www.fiber-life.com.