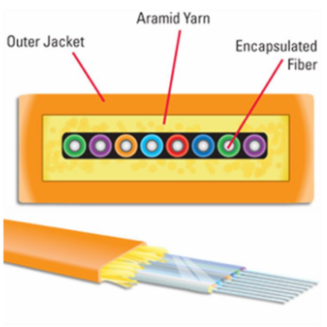

Armored Cables are designed with an additional layer of protection surrounding the fiber core, typically utilizing metals such as steel or aluminum, or durable synthetic materials. This armor layer shields the delicate fibers from external damage, ensuring reliable operation even in harsh environments.

Why Opt for Armored Cables?

The extra protective layer helps prevent damage from crushing, pulling, bending, and animal bites, making these cables ideal for installations in tough conditions.

Applications: Armored cables are often deployed in locations where standard cables are at risk, including urban, industrial, outdoor, and underground settings.

Key Factors to Consider When Selecting Armored Cables

When choosing armored cables, several factors must be considered to ensure they meet the specific needs of your project. Here are some main elements to evaluate:

Type of Armor Material

- Steel Armored: Commonly used in industrial applications, steel-armored cables provide robust protection but are heavier, which may limit flexibility.

- Aluminum Armored: Offers a lighter alternative to steel while still providing significant protection. Aluminum is often preferred for projects requiring a balance between durability and weight.

- Non-Metallic Armored: Made from synthetic materials, non-metallic options are corrosion-resistant and suitable for areas sensitive to electromagnetic interference (EMI).

Cable Flexibility and Installation Requirements

If your installation involves tight spaces, bends, or frequent movement, consider cables with flexible armor. While metal armor offers strength, it can be rigid, making non-metallic armor or lightweight aluminum options potentially better suited for flexibility needs.

Environment and Exposure Conditions

- Indoor vs. Outdoor: Outdoor armored cables require UV resistance and weatherproofing. Indoor applications may not need these features and can often use simpler (and less costly) options.

- Temperature Range: In environments with extreme temperatures, select a cable rated for those conditions. Cables used in hot industrial areas or cold outdoor installations should be tested to withstand those extremes.

Rodent-Resistant Features

Armored cables are often deployed underground or in industrial areas where rodents might chew through unprotected cables. Steel or aluminum armor effectively deters rodents, making it ideal for such conditions.

Practical Tips for Selecting the Right Armored Cables

To ensure you’re choosing the most effective Armored Cables for your needs, follow these practical tips:

- Assess the project’s environmental challenges

- Evaluate cost vs. durability

- Consider future maintenance

Important Considerations for Armored Cables Installation

Selecting the right cable is only the first step; proper installation is crucial for maximizing the cable’s durability and performance. Here are some tips and warnings:

- Avoid overbending

- Use appropriate connectors and termination kits

- Protect against moisture

- Ensure correct grounding

Final Thoughts: Choosing the Right Armored Cables for Your Needs

Selecting an Armored Cables is about matching the right features to your project’s demands. Whether you’re installing cables in a high-traffic industrial environment, underground urban area, or outdoor setting, choosing the right type of armor, understanding the installation requirements, and anticipating future needs can make all the difference.

By following these guidelines, you can confidently choose an Armored Cables that will protect your network, meet your project’s unique demands, and provide reliable performance for years to come.