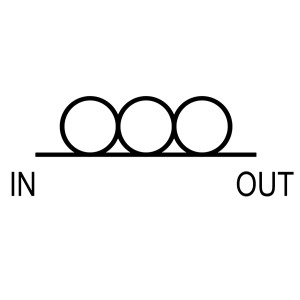

According to different packaging methods, PLC optical splitters can be divided into bare fiber type, micro (steel tube/module), with fanout type, ABS box type, tray type, rack type, etc. There are many types of splitting ratios for PLC optical splitters, the most common of which are 1:8, 1:16, 1:32, 1:64, 2:8, 2:16, 2:32 and 2:64.

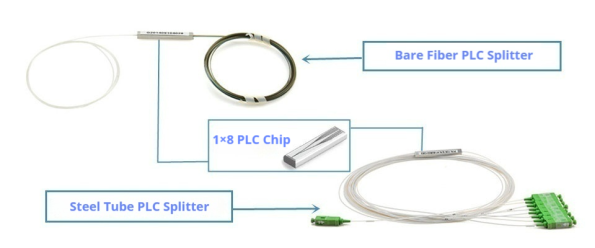

Bare fiber PLC optical splitter

Bare fiber PLC optical splitters and miniature steel tube PLC optical splitters are the smallest of all PLC optical splitters (as shown in the figure below). Bare fiber PLC optical splitters are often installed in various types of pigtail boxes, various types of test instruments, and WDM systems. The appearance of the miniature steel tube PLC optical splitter is similar to that of the bare fiber PLC optical splitter. The difference is that each optical fiber of the miniature steel tube PLC optical splitter is terminated with a fiber optic connector and is often installed in optical cable joint boxes, module boxes, and distribution boxes.

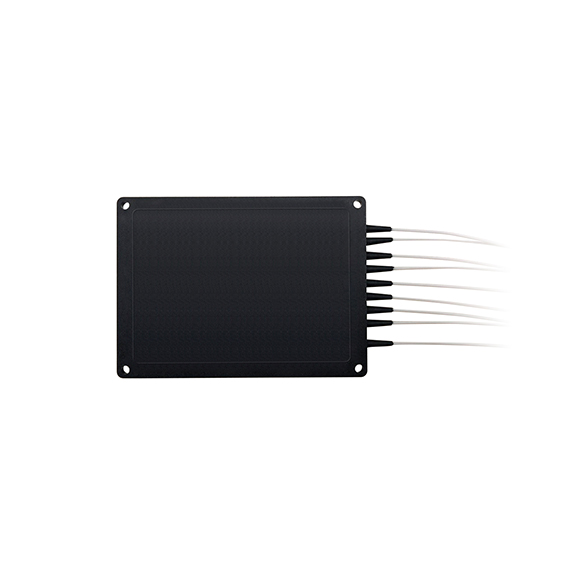

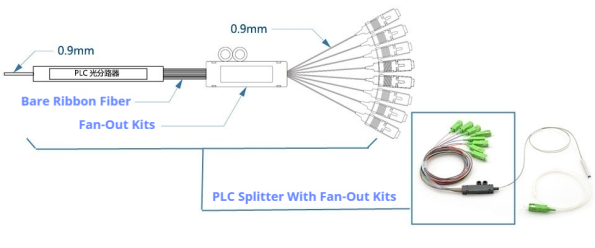

PLC optical splitter with fanout kits

The PLC optical splitter with fanout kits is designed for flexible management of optical cables in limited space. Both the input and output ends use 0.9 mm optical fiber. The output end of the PLC optical splitter with splitter has a splitter and multiple branch optical cables (as shown in the figure below). It is usually installed in various types of optical distribution equipment and various types of optical test instruments.

ABS box type PLC optical splitter

As shown in the figure below, the ABS box type PLC optical splitter uses a plastic ABS box to protect the optical waveguide chip and the optical fiber array board. It has a high level of protection and is suitable for direct application under engineering construction conditions.

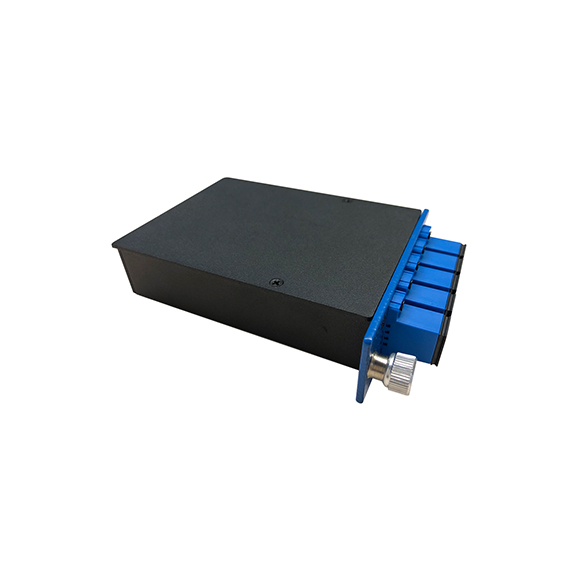

LGX Box Type PLC Optical Splitter

Unlike ABS box-type PLC optical splitters, the optical waveguide chip, fiber array board and optical cable of the LGX box-type PLC optical splitter are all installed in the metal LGX box. It can be used alone or installed in a distribution box (as shown in the figure below). In addition, the LGX box-type PLC optical splitter is also pre-terminated with a fiber adapter, which can quickly achieve reliable fiber connection. LGX box-type PLC optical splitters are becoming more and more common in FTTH applications.

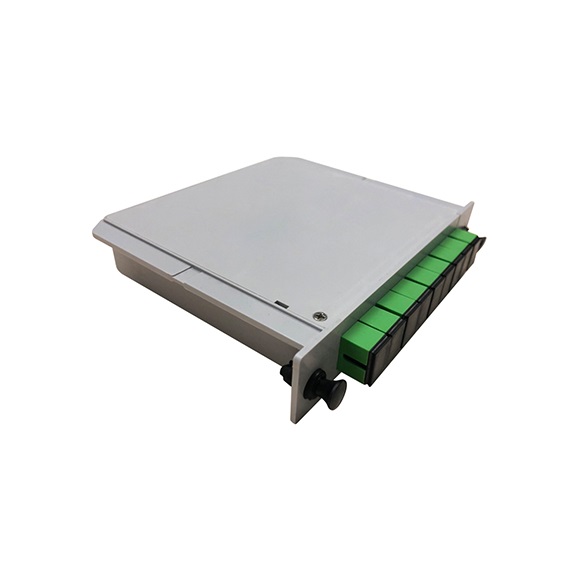

Plug-in PLC optical splitter

The structure of the plug-in PLC optical splitter is very compact, and it looks like a smaller version of the LGX box-type PLC optical splitter (as shown below). It is used for user access points in the FTTX system that require optical splitting. It mainly completes the termination of optical cables entering the community or building, and has functions such as optical fiber fixing, stripping, splicing, jumper, and splitting. After splitting, it enters the end user in the form of a home optical cable. The plug-in PLC optical splitter can be installed in a 19-inch rack or indoor or outdoor wall-mounted box, with high installation density and large capacity.

Tray type PLC optical splitter

The tray-type PLC optical splitter is an optical splitter placed in a rack-mounted distribution box. This type of optical splitter can be installed and used on various outdoor optical cable junction boxes, ODF distribution frames, rack-mounted ODBs and other equipment. It is commonly used in optical line terminals (OLTs) and optical network units (ONUs).

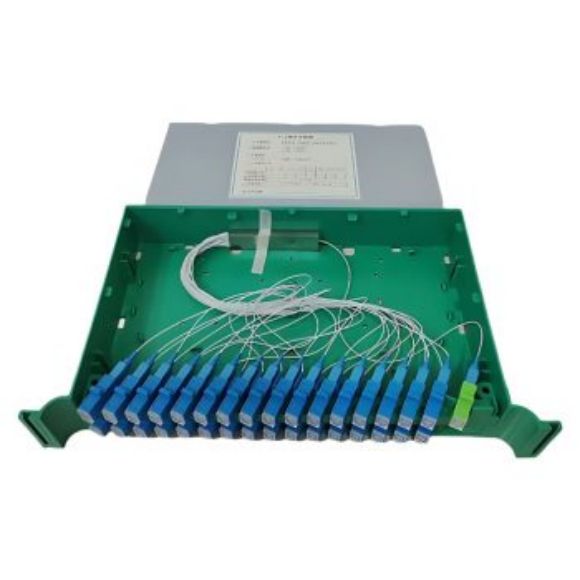

Rack mount PLC optical splitter

The rack-mounted PLC optical splitter adopts a 19-inch standard structure design. The front panel contains an adapter installation panel and can provide different adapter interfaces according to customer needs. It is mainly used for installation on a 19-inch rack or cabinet. It can also be widely used in various 19-inch installation structures of indoor integrated access boxes and wall-mounted boxes.