At FiberLife, we have shared numerous tips and guides on high-performance network cabling in our blog and community. However, you might wonder about the unique advantages that 50-micron fiber patch cables offer over traditional single-mode and multimode fibers. Today, we will explore the distinctive features of these fiber patch cables and explain why they are the top choice for modern data centers and enterprise networks. FiberLife aims to help you select high-quality 50-micron fiber patch cables and identify reliable suppliers, ensuring your network cabling is both efficient and dependable. Let’s dive in!

Key Indicators of Product Quality

Core Diameter

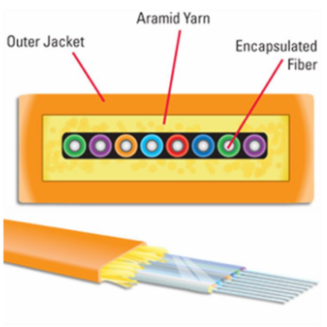

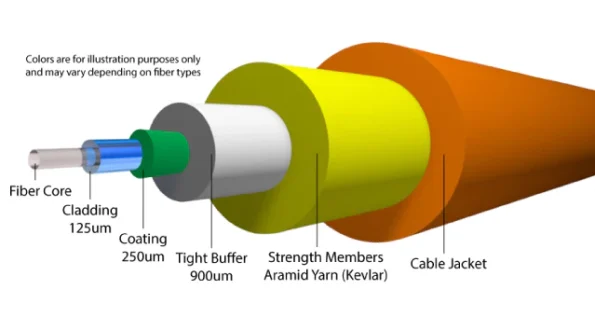

When selecting a high-quality 50-micron fiber patch cable, the first aspect to consider is the core diameter. A 50-micron fiber patch cable has a core diameter of 50 microns, providing high bandwidth and low loss transmission performance. Ensuring that the supplier provides fiber patch cables that meet this standard is the first step in guaranteeing quality. This crucial parameter determines the transmission capability of the fiber patch cable. Especially in data centers and high-performance computing environments, the correct core diameter ensures high-speed and stable networks.

Insertion Loss and Return Loss

Insertion loss and return loss are also critical metrics for measuring fiber patch cable quality. High-quality fiber patch cables should have low insertion loss and high return loss. The lower the insertion loss, the better the signal transmission; the higher the return loss, the less signal is reflected back. Choosing products with insertion loss less than 0.3dB and return loss greater than 35dB can significantly enhance network stability and reliability.

Fiber Type and Jacket Material

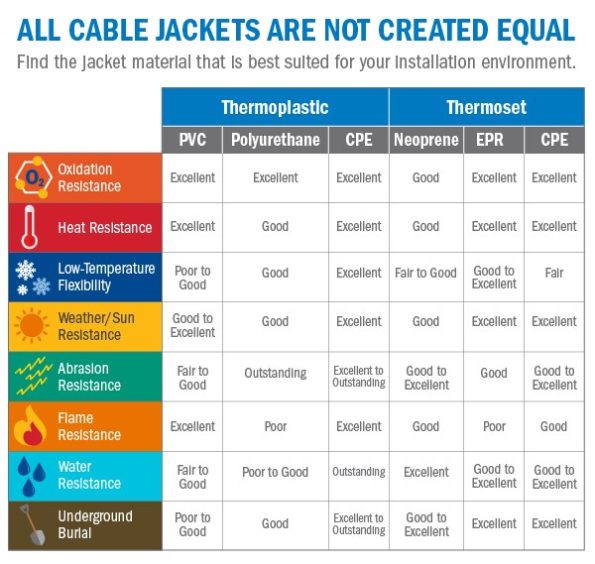

Beyond core metrics, the fiber type and jacket material of the fiber patch cable significantly impact its performance. Ensure that the fiber patch cable uses internationally standardized multimode fibers such as OM2, OM3, or OM4, which offer different transmission distances and bandwidths. OM3 and OM4 fibers are typically used in environments with high bandwidth demands, such as data centers, due to their ability to provide higher bandwidth over longer distances. Regarding jacket materials, LSZH (Low Smoke Zero Halogen) materials can reduce the release of toxic gases during a fire, ensuring safety. Choosing jacket materials that meet environmental and safety standards helps protect the environment and ensures safety during use.

Connector and End-Face Quality

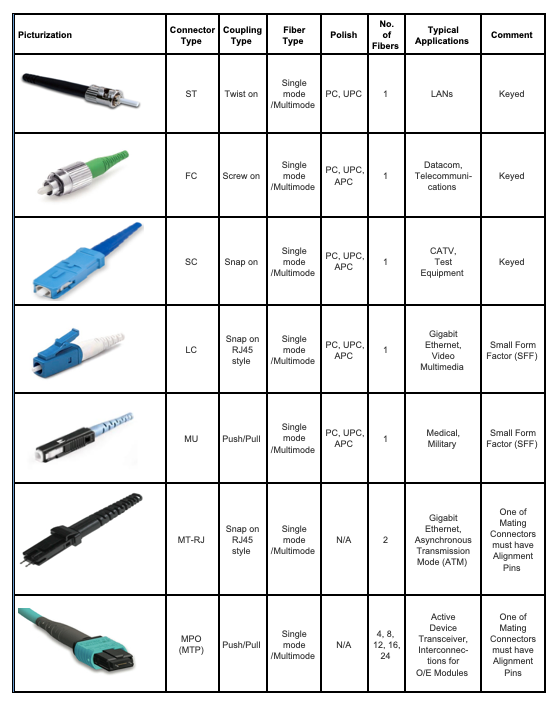

Connector and end-face quality are critical factors affecting fiber patch cable performance. High-quality fiber patch cables should use premium connectors, such as LC, SC, and ST, with smooth and flawless connector end-faces. Check the ceramic ferrule of the connector and the end-face polishing process to ensure connection stability and transmission reliability. High-quality connectors and end-face polishing can reduce signal loss, improve transmission performance, and extend the lifespan of the fiber patch cable.

How to Identify High-Quality Fiber Patch Cables

Visual Inspection

Visual inspection is a simple yet effective method when selecting fiber patch cables. Before purchasing, visually inspect the fiber patch cable to check whether the outer sheath is intact, the connectors are secure, and the end-face is clean and free of scratches. This process helps users initially assess the appearance quality and workmanship of the fiber patch cable, eliminating obvious quality issues.

Performance Testing

Performance testing is an essential means of ensuring fiber patch cable quality. Choose suppliers who can perform performance testing to ensure the insertion loss, return loss, transmission distance, and other metrics of the fiber patch cable meet requirements. You can request suppliers to provide test reports. Through these professional test data, users can more accurately understand the actual performance of the fiber patch cable, ensuring it meets specific usage needs.

Brand and Certification

Brand and certification are also key factors in identifying high-quality fiber patch cables. Choose fiber patch cables from well-known brands and check whether the products have relevant certifications, such as RoHS, CE, and UL. These certifications ensure the product’s environmental friendliness and safety, providing additional quality assurance. Well-known brands usually have a good market reputation and technical support, offering users higher quality products and services, thus reducing usage risks.

Choosing a Reliable Supplier

Industry Certification and Market Reputation

Selecting a supplier with industry certification and a good market reputation is crucial for ensuring fiber patch cable quality. Industry certification demonstrates the supplier’s professionalism and production capability, while a good market reputation reflects the supplier’s service quality and product reliability. Check the supplier’s official website, industry association member lists, and customer reviews to understand the supplier’s qualifications and reputation.

Service Support and After-Sales Guarantee

Besides product quality, the service support and after-sales guarantee of the fiber supplier are essential considerations. Choosing a supplier that can provide timely and professional service support can help resolve issues during use, ensuring stable network operation. Additionally, understanding the supplier’s after-sales guarantee policies, including return and exchange policies and warranty periods, provides extra assurance and reduces usage risks.

Comprehensive Consideration

When choosing a 50-micron fiber patch cable supplier, considering the above factors comprehensively is key to ensuring the selection of high-quality products. By understanding the key indicators of the product, identifying high-quality fiber patch cables, and choosing reliable suppliers, users can more accurately select 50-micron fiber patch cable products that meet their needs, ensuring network stability and reliability.

Conclusion

In today’s rapidly evolving network technology landscape, selecting a high-quality 50-micron fiber patch cable is a crucial step in ensuring network performance. By focusing on key product indicators, identifying high-quality fiber patch cables, and choosing reliable suppliers, users can select high-performance, reliable 50-micron fiber patch cable products that ensure high-speed and stable network operation.

Moreover, FiberLife’s latest IP67 LC To Duplex LC OM2 Multimode TPU Fiber Cable is a noteworthy product. Its design and performance excel in various applications. This product uses OM2 multimode fiber, offering excellent transmission capability, making it ideal for high-bandwidth and low-latency network environments. The TPU jacket material of this fiber patch cable is not only wear-resistant and torsion-resistant but also has excellent environmental adaptability, maintaining stable performance under various harsh conditions. The IP67-rated protection design ensures reliable operation in wet or dusty environments, making it an ideal choice for indoor and outdoor cabling.

Choosing FiberLife’s IP67 LC To Duplex LC OM2 Multimode TPU Fiber Cable allows you to experience stable and efficient network connections and enjoy FiberLife’s excellent after-sales service and technical support. Whether for enterprise applications or data center cabling, this product can meet your needs and enhance overall network performance. Visit our website to learn more about the bend-insensitive patch cable. Seize the opportunity to upgrade your network cabling and enjoy an unprecedented high-speed transmission experience! FiberLife looks forward to building the network world of the future with you.