When it comes to the most popular configurations in electrical and communication facilities, Armored Cables must be among the top three, because of its excellent durability and protection performance, which is very suitable for outdoor environments. Today, we will share with you the characteristics and advantages of Armored Cables, as well as the places where they are used. Don’t miss it if you are interested in this.

Armored Cables Features

What are armored cables?

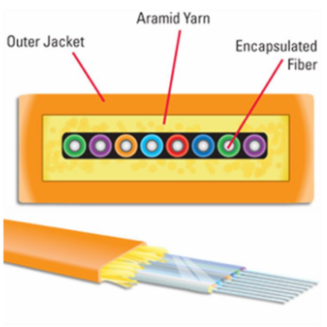

Armored fiber optic cables, also known as armored sheathed cables, are electrical cables with an outer protective layer made of metal or non-metallic materials. This layer provides mechanical protection against physical damage, moisture, and other environmental factors. If you’d like to delve deeper into the topic of armored fiber optic cables, check out our article What Is Armored Fiber Cable? for a comprehensive understanding.

What is the difference between indoor armored cables and industrial cables?

Indoor armored patch cables can prevent rat bites and stampedes, suitable for an indoor harsh environment. Industrial grade fiber cables are also armored, waterproof, and ultraviolet, cold and high temperature resistant, suitable for the outdoor environment.

How much can I bend FS armored fiber?

Armored fiber optic cables have specified bend radii based on their outer diameter. The cable bend radius should not be smaller than the recommended minimum value. The minimum bend radius for FS single-mode armored fibers is typically 10/5D (Dynamic/Static), while for multimode it is 20/10D (Dynamic/Static). Specific parameters may vary depending on the type. Reviewing the manufacturer’s instructions before installation is important to determine the cable’s minimum bend radius.

This representation associates the minimum bend radius with the outer diameter (D) of the cable proportionally. In this case, during installation or wiring, the cable should have a minimum bend radius of 20 times the outer diameter. However, during operation, the cable can have a minimum bend radius of 10 times the outer diameter.

Armored Cables Benefits

How do armored cables differ from unarmored cables?

Structure: Armored fiber cables have an additional layer of protection surrounding the inner conductors. This layer, made of metal or non-metallic materials, acts as a shield against physical damage. Unarmored cables, on the other hand, lack an additional protective layer. While they offer basic insulation, unarmored cables are more vulnerable to physical damage and environmental hazards than armored cables.

Application: Armored cables are commonly used in applications where there is a high risk of physical damage or exposure to harsh conditions. Unarmored cables are commonly found in indoor installations, residential wiring, and low-risk commercial settings where protection from external factors is not a major concern.

Can armored fibers be installed in wet locations?

FS offers armored cables with waterproof capabilities, such as IP67 rating. Standard armored fiber cables are suitable for use in mildly damp environments. However, prolonged submersion in water for a long time may impact their longevity. For detailed information, please visit our website.

Armored Cables Application

Where are armored cables commonly used?

Indoor armored cables enable the installation of optical fiber in highly challenging environments, including areas with slight dust, oil, gas, moisture, or the presence of rodents and pests that could cause damage.

Armored industrial cable features strong tensile strength, strong pressure resistance, and good flexibility characteristics. Besides, it is bending-resistant, oil-resistant and wear-resistant. As a result, armored industrial cables are well-suited for both indoor and outdoor applications, such as connecting networks between buildings through underground conduits or direct burial.

How to cut armored fiber?

You can use various tools to cut armored fiber optic cables. The best option is to use cable cutters specifically designed for this task. Alternatively, you can use diagonal cutters or a hacksaw as substitutes. Follow these steps to safely and effectively use cable cutters:

1. Accurately measure the required cable length and mark the outer sheath at the cutting point.

2. Adjust the blade depth of the tool to ensure the correct depth for cutting the armor.

3. Place the cable in the wire guide of the cutter, align it with the marked cutting point, and secure it in place.

4. Carefully cut.

5. Remove the newly cut cable from the cutter.

At Last

If you or someone you know wants to buy Armored Cables, then FiberLife can help you with that. As a global supplier of fiber optic solutions and networks, we have become renowned for our high-quality products. Our wide range of products includes DWDM modules, optical amplifiers, MPO Trunk cables, Fiber Breakout cables, and a lot more. Call us today and learn more about our fiber optic couplers in detail.