Corning Bare Fibers have earned a stellar reputation in the fiber optics industry for their exceptional quality and adaptability. Manufactured by Corning, a pioneer in glass and ceramics, these fibers have become indispensable in settings where dependable, high-performance fiber is paramount. This article delves into the essence of Corning Bare Fibers, their distinctive advantages, and their role in various professional scenarios.

What Are Corning Bare Fibers?

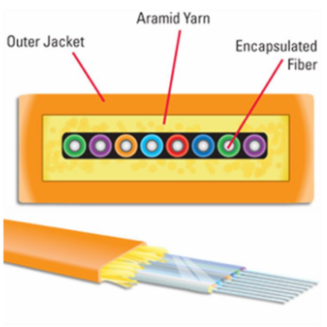

Corning Bare Fibers are the unbuffered, uncoated strands of optical fiber produced by Corning. Unlike conventional fiber optic cables that are enveloped in protective layers, bare fibers are stripped to their essential elements. Predominantly intended for laboratory use, temporary connections, or test configurations, these fibers offer pure fiber connections devoid of any additional protective material.

This minimalist design endows Corning Bare Fibers with unparalleled versatility and value in applications demanding precision and control over fiber characteristics.

Key Advantages of Corning Bare Fibers

Corning Bare Fibers boast a suite of unique advantages that position them as the preferred choice for a myriad of professional scenarios:

- High-Quality Fiber Construction: Corning’s state-of-the-art glass manufacturing processes yield fibers of superior quality and reliability. These fibers exhibit consistent attenuation and minimal signal loss, ensuring steadfast performance even in the most demanding applications.

- Flexibility for Testing and Prototyping: The absence of a protective coating renders bare fibers incredibly lightweight and pliable, making them perfect for environments where testing or prototyping fiber connections is required without the rigidity of jacketed fibers.

- Customization Options: Bare fibers permit technicians and engineers to apply bespoke coatings or pair them with specific connectors, offering enhanced flexibility for specialized applications.

- Cost-Effective for Temporary Connections: Often more economical than fully-packaged cables, Corning Bare Fibers are an ideal choice for short-term setups, experiments, or temporary connections.

Common Applications of Corning Bare Fibers

Given their unique attributes, Corning Bare Fibers thrive in a variety of specialized environments:

- Laboratory Research and Testing: Fiber optic technology-focused laboratories rely on bare fibers for testing and analysis. Their unjacketed form facilitates experiments, tests of various transmission qualities, and optical measurements. Additionally, bare fibers are instrumental in research labs for the development and innovation of optical communication technology.

- Field Testing and Temporary Connections: In field installations, engineers frequently require temporary connections or quick fixes before establishing a permanent setup. Corning Bare Fibers enable swift and straightforward connections, providing reliable data transmission on a temporary basis until the final fiber infrastructure is in place.

- Educational and Training Environments: For educational institutions or training programs centered on fiber optics, bare fibers are ideal for hands-on learning. They offer a practical, cost-effective solution for students and trainees to handle real fiber without the additional cost of connectors or jackets.

- Telecommunication and Data Transmission Experiments: Telecommunication companies and data centers may utilize Corning Bare Fibers to test data transmission rates or analyze the fiber’s performance under diverse conditions. The bare fibers provide precise readings, assisting organizations in refining their setups.

How to Handle and Work with Corning Bare Fibers

While incredibly useful, bare fibers necessitate careful handling. Here are some tips for effectively working with Corning Bare Fibers:

- Use Protective Coatings if Needed: For certain applications, it may be prudent to add a protective coating to the fiber post-testing or experimentation. This enhances durability without compromising the flexibility inherent to bare fiber.

- Employ Dust and Scratch Protection: As bare fibers lack a protective jacket, they are vulnerable to damage from dust and scratches. Always handle the fiber with clean hands and use dust caps or other protective measures when storing.

- Consider Heat Sensitivity: Like other optical fibers, Corning Bare Fibers can be sensitive to heat. Avoid exposing them to high temperatures, especially when the fibers are bare and unprotected. Excessive heat could lead to warping or damage, affecting their transmission quality.

Selecting Corning Bare Fibers for Your Project

When selecting bare fibers, it is crucial to assess your project’s requirements. Consider the following:

- Evaluate Your Performance Requirements: For critical applications requiring low signal loss or high attenuation, Corning’s bare fibers are an excellent choice due to their quality and performance stability.

- Consider Your Setup Environment: Bare fibers perform best in controlled environments such as labs or temporary setups where physical protection is not a significant concern. For outdoor or long-term setups, you might consider fibers with additional coating or jacketing.

- Review Cost vs. Application Needs: If the project is temporary or for testing purposes, bare fibers are a cost-effective solution. For long-term, high-stress applications, investing in jacketed or coated fiber might offer better value in terms of durability.

Conclusion: Why Choose Corning Bare Fibers?

Corning Bare Fibers offer unique flexibility and performance for specialized applications, making them ideal for labs, training environments, and temporary setups. They deliver high transmission quality, customization potential, and cost-effectiveness, particularly in controlled environments. By understanding the specific benefits and handling requirements, you can harness Corning Bare Fibers to enhance your fiber optic experiments, testing, or short-term installations.

Whether you are in telecommunications, conducting laboratory research, or training future fiber optic experts, Corning Bare Fibers provide the high performance and adaptability needed for precise, effective fiber installations. With careful handling and attention to application-specific needs, they can be an invaluable asset in your fiber optic toolkit.