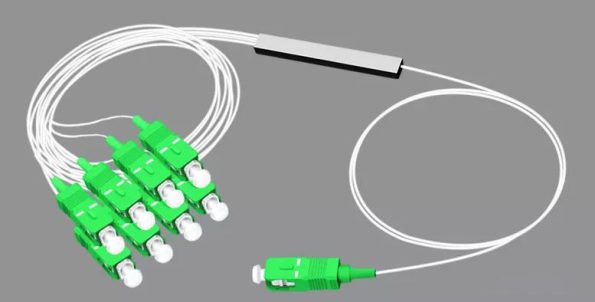

A fiber splitters is an optical device that can distribute optical signals from one optical fiber input to multiple output ports. It plays a vital role in optical fiber communication systems, especially in passive optical networks (PONs). Fiber splitters can effectively split optical signals into several signals of equal proportions and distribute them to different user terminals, thereby realizing the function of multiple users sharing one optical fiber line. According to the manufacturing process, fiber splitters can be divided into PLC Splitters and FBT Coupler Splitters, both of which have their own advantages in performance and application scenarios.

The working principle of fiber splitters is relatively simple, and the signal distribution is achieved through the principle of optical coupling in optical fibers. However, choosing the right splitter type and splitting ratio is crucial to optimizing the performance of communication networks. PLC Splitters are suitable for large-scale distribution with high stability and low loss, while FBT Coupler Splitters are more suitable for small-scale branches with lower costs.

Classification of Fiber Splitters

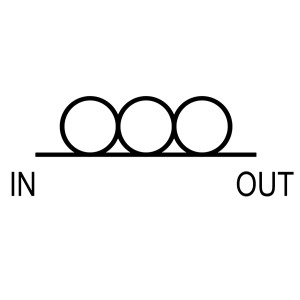

Optical splitters can be classified into two types based on the splitting principle: fused biconical taper (FBT Coupler Splitters) and planar lightwave circuit (PLC Splitters). The FBT method involves fusing and stretching two or more fibers at high temperatures to form a special waveguide structure. By controlling the twisting angle and stretching length of the fibers, different splitting ratios can be achieved. The downside of this manufacturing process is that the thermal expansion coefficient of the curing adhesive differs from that of the quartz substrate and stainless steel tube, which can lead to damage to the Fiber Splitters, especially when exposed to outdoor environments. For splitters with more output channels, multiple two-way splitters can be combined.

PLC splitters, on the other hand, are made using semiconductor processes such as photolithography, etching, and development. The waveguide array is located on the upper surface of the chip, and the splitting function is integrated on the chip, achieving 1×N splitting; then, the input and output multi-channel fiber arrays are coupled at both ends of the chip and encapsulated.

Packaging Forms of Fiber Splitters

The packaging of Fiber Splitters should be economical, efficient, robust, and compact. The internal fibers of the device should ensure a certain winding radius to protect the fibers from damage. All components should be securely fixed and provide sufficient space for management, connection, installation, maintenance, inspection, and testing. Common packaging forms for Fiber Splitters include:

- Steel tube mini Fiber Splitters

- ABS box packaging

- Plug-in packaging

- Tray packaging

- 1U rack-mount packaging

Application Scenarios for Fiber Splitters

Fiber Splitters are mainly used in the following scenarios in practical applications:

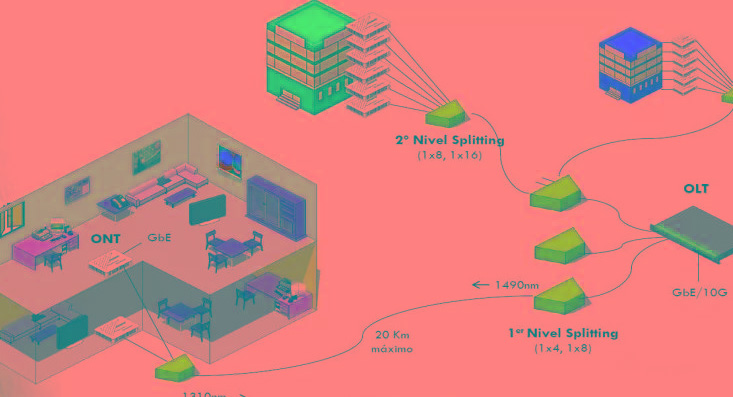

- FTTH (Fiber To The Home), OLT (Optical Line Terminal) and ONU (Optical Network Unit)

- Optical monitoring, commonly used by public security network supervision departments

- Erbium-doped fiber amplifiers

- Fiber optic sensing systems

- Optical protection OLP systems

Features and Disadvantages of Fiber Splitters

The main advantages of the fused biconical taper technology include:

- Over twenty years of history and experience, with many devices and processes that can be continued as is.

- Raw materials are easily obtainable, and costs are low.

- The splitting ratio can be monitored in real-time, allowing for the creation of unequal splitting ratios.

The main disadvantages include:

- Loss is sensitive to optical wavelength, making it unsuitable for multi-wavelength signal transmission.

- Uniformity is poor, which may affect overall transmission distance.

- Insertion loss varies significantly with temperature.

- Multi-channel splitters are large, have lower reliability, and are limited in installation space.

The main advantages of planar lightwave circuit (PLC) optical power splitters include:

- Loss is insensitive to the transmission wavelength, suitable for different wavelengths.

- Uniform splitting, evenly distributing signals to users.

- Compact structure, small size, easy to install.

- A single device can have many splitting channels, with lower costs.

The main disadvantages include:

- The manufacturing process is complex, with high technical barriers.

- The cost is higher compared to fused biconical taper splitters, especially for low-channel splitters.

Technical Requirements for Custom Fiber Splitters

- Specify the use of fused biconical taper (fiber coupling type) Fiber Splitters.

- Determine the structural form, such as 19-inch rack-mount, FC/APC, or SC/APC connectors.

- Determine the central wavelength and bandwidth, such as single wavelength 1310nm, 1550nm, or broadband types.

- Require an upper limit for additional loss, such as 0.2dB for 2 channels, 1.2dB for 16 channels.

- Determine the splitting ratio, accurate to one decimal place.

In summary, fiber splitters are key equipment for building efficient optical communication networks, and their selection and deployment need to be rationally planned according to specific network requirements and budgets. Whether it is a large-scale communication operator network or a small and medium-sized enterprise network, fiber splitters can help achieve efficient signal transmission and maximize resource utilization. In practical applications, the rational selection of PLC Splitters or FBT splitters can ensure the stability, flexibility and long-term scalability of the network.