Traditional optical fiber connections involve assembling various Fiber Adapters fiber optic connectors with raw optical fibers of specific lengths and processing them into patch cords in the factory. This process encompasses a series of intricate technical procedures such as threading, fiber ferrule assembly, ferrule injection, colloid curing, fiber cutting, degumming, rough grinding, intermediate grinding, fine grinding, and polishing.

In optical communication, there is often a need to temporarily connect bare fibers with optical fiber equipment, and it is usually too late to fabricate patch cords on-site. Optical fiber fusion is an option, but it requires a splicer and can only address the connection of two optical fibers, not the issue of connecting bare fibers to the interfaces of optical fiber equipment. The use of bare fiber adapters allows for direct connection and coupling of bare fibers with other optical devices.

I. What is a Bare Fiber Adapters?

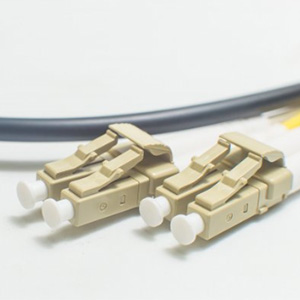

A bare fiber optic adapter serves as an intermediary for connecting raw optical fibers to fiber optic equipment. One end of the adapter is designed to attach to bare fibers, while the other end features a fiber optic connector.

Bare fiber optic adapters are primarily used to test bare fiber patch cords and pigtails that lack end face treatment. The bare fiber can be directly connected to standard connectors such as FC, SC, ST, and LC to measure connection loss. By simply peeling off the coating and cutting the end face, the bare optical fiber can be inserted into the adapter. This allows the bare fiber to function as a temporary connector with a fiber optic connector for testing and temporarily connecting optical fiber devices or systems, simplifying the operation.

An additional advantage of bare fiber optic adapters is their recyclability, making them convenient and cost-effective. They are particularly suitable for connecting to optical power meters, optical time domain reflectometers (OTDRs), and various other instruments. They facilitate emergency connections during field wiring situations and enable on-site functional testing without the need for additional permanent connectors. For technicians and contractors, this makes fiber testing and network maintenance easier, faster, and more efficient.

II. Applications of Fiber Adapters

- Temporarily connecting exposed fibers.

- Testing bare fibers, fibers on reels, and fibers before and after installation.

- Production lines of 5G optical fiber equipment.

- Providing quick and temporary fiber optic connections in communication systems.

III. How to Use Bare Fiber Adapters?

- Stripping Fiber: Use an optical fiber stripper to remove the coating layer of the optical fiber, typically 15 to 20 mm in length. Adjust the length according to the specific bare fiber adapters being used, then clean the fiber with alcohol or lint-free paper.

- Inserting the Bare Fiber into the Adapter: Press and hold the spring-loaded button on the adapter, depress the switch, and gently push the fiber into the guide hole until the ceramic ferrule protrudes by approximately 3-5 mm. Release the switch to secure the fiber in place. Inspect the condition of the fiber end face and make adjustments if necessary.

- Gently score the bottom of the fiber with an optical fiber scribing pen, then break the fiber to complete the operation.

The connector on the bare fiber adapters can then be mated with the connector end through the adapter, allowing for optical parameter testing. If the test results are unsatisfactory, ensure the fiber end is properly cut, recut it if needed, and retest. Components of the bare fiber that pass the parameter tests can be utilized or spliced into the system.