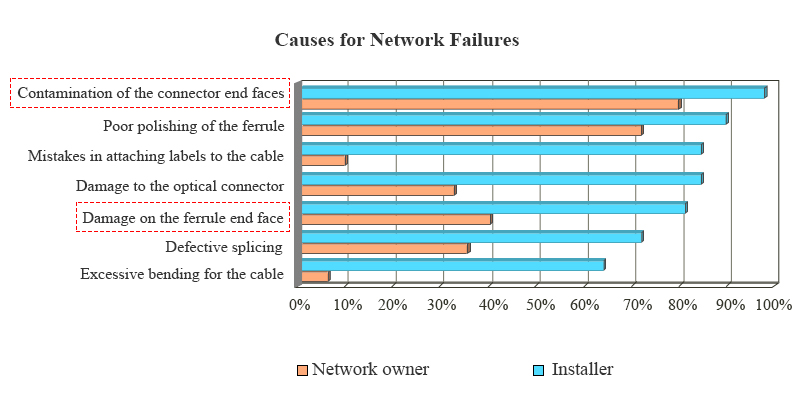

According to NTT-Advanced Technology, an alarming 98% of installers and 80% of network owners have reported that fiber connectors contamination is the primary cause of network failures. Contaminated or dirty fiber connectors can lead to degraded signal performance or even link failure. Therefore, maintaining and cleaning fiber optic cables is crucial to minimize contamination on fiber interfaces. Fiber cleaning kits are indispensable for the upkeep of fiber optic systems, ensuring effective connections across all fiber optic equipment.

Diverse Fiber Connectors Types and Their Impact

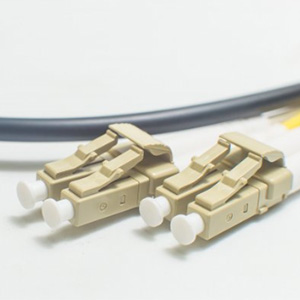

Fiber connectors are critical components that terminate the ends of fiber optic cables, significantly influencing the reliability and performance of fiber optic transmission systems. Over 100 types of fiber optic connectors have been introduced to the market, including the widely used LC, SC, MU, ST, FC, MTRJ, NID, E2000, and MTP/MPO connectors in data centers. Additionally, specialized connectors like Rosenberger Q-RMC or NEX10 are designed for harsh environments. Selecting the appropriate fiber cleaning tools is contingent upon the type of fiber connectors in use.

Mastering General Fiber Cleaning Procedures

Before engaging in fiber optic connector cleaning, it is imperative to understand the general process, which typically involves two methods: dry and wet cleaning. Dry cleaning utilizes a reel-type cassette cleaner or a push-type fiber cleaner to wipe the connector end face in one direction against a dry cleaning cloth, primarily removing airborne contamination. This method should be the first approach attempted. Wet cleaning involves wiping the end face first against a wet area and then onto a dry area to remove any potential residue. This method is more aggressive than dry cleaning and is capable of removing both airborne contamination and light oil residue. If the connector remains dirty after dry cleaning, wet cleaning should be performed immediately to ensure no residue is left on the end face.The following shows the fiber connector cleaning process:

A Variety of Fiber Connectors Cleaning Solutions

Reel-Type Fiber Cleaners: Designed for effective cleaning of a wide range of accessible ferrule connectors, including LC, MU, SC, FC, ST, MPO/MTP, MTRJ, etc., these cleaners are ideal for those needing to clean a variety of connector styles.

NEOCLEAN-R2 Fiber Optic Cassette Cleaner: This essential tool supports the removal of dust, oil, and other debris for various connectors and offers over 400 cleaning cycles.

Fiber Cleaning Wipes: These wipes are designed for dry or alcohol-assisted use, effectively removing common contaminants from optical jumpers and patch cords. They are lint-free and non-abrasive, ensuring superior cleaning without the risk of scratching or leaving lint residue.

Foam Swabs: Ideal for cleaning 1.25mm or 2.5mm fiber adapters and connectors, these polyester and polyurethane swabs provide excellent performance in cleaning the end face of adapters or connectors and can also be used for other equipment such as printers, computers, and optical instrument camera lenses.

Pen Cleaners: Fiber-Life’s one-push fiber optic cleaning pen quickly removes dirt, dust, oil, and grease from optical fiber adapters. Available in various models to cater to different cleaning needs, including NEOCLEAN pen cleaners for specific connector types and US Conec IBC™ Brand Cleaners.

Procuring Fiber Cleaning Kits

To mitigate link failures and the unnecessary replacement of costly and critical network equipment, it is highly advisable for data center facilities to establish cleaning procedures for all fiber optic connectors. A multitude of solutions exists for supplying test and inspection equipment, as well as fiber optic cleaning supplies. Fiber-Life offers a comprehensive selection of compact fiber optic cleaning kits tailored to specific application needs. For further information, please reach out to us at sales@Fiber-Life.com.