In today’s data centers, high-speed computing and telecommunications networks, optical cables have become an indispensable transmission medium. In particular, MTP®/MPO Optical Cables are valued for their high-density connection capabilities. However, how to ensure the quality of these high-performance optical cables has become a challenge for users and manufacturers. This article will answer your questions in detail.

Factors to Distinguish High-quality MTP®/MPO Cable

To buy the best MTP® cable, many factors can be taken into consideration. Here are five main features that a high-quality MTP® cable should have.

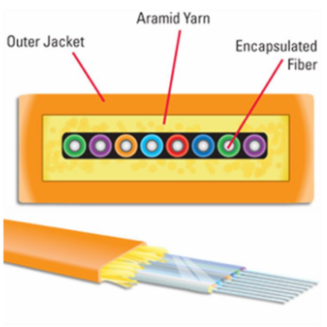

(1) Brand Fiber Core Can Ensure the Optimized Performance

MTP®/MPO networks are often deployed in small spaces, such as telecommunications distribution boxes, data center cabinets, etc. In these cases, the fiber core will be bent at a small angle. If a poor fiber core is bent at a small angle, it will often cause signal loss, resulting in high transmission interruption. Normally, brand fiber core like Corning ClearCurve fiber has greatly improved the bending performance, which minimizes signal loss and enables faster and more efficient fiber optic cable routing, installation, and cabling. Therefore, MTP® cable with brand fiber core is very important.

(2) Industry Recognized MTP® Connector Is Important

MTP®/MPO fiber connectors can package 12, 24, or 72 fibers into a ferrule to increase fiber density. Therefore, they are popular in space-constrained data centers. Industry recognized MTP® or MPO connector, offers precision alignment of the female and male sides, which can reduce insertion loss and return loss. It has a solid structure that is durable to meet hundreds of mating cycles. The joint of the connector and the wire uses a round multi-core cable, which could be routed and mechanically loaded from any direction of the MTP® connector port, facilitating the cable installation. Therefore, to buy the best MTP® cable, an industry recognized MTP® connector also matters.

(3) Low Insertion Loss Is a Key Factor

Insertion loss (IL) refers to the loss of effective optical power of a link caused by the insertion of a connector or plug. It is one of the key factors affecting the performance of fiber optic networks. The smaller the insertion loss, the better the network performance. The IL of a conventional multi-mode MTP® ferrule should generally not exceed 0.6 dB, and the conventional single-mode MTP® ferrule should generally not exceed 0.75 dB. For single-mode and multi-mode MTP® with low insertion loss (high quality), it is generally required that the insertion loss does not exceed 0.35 dB. When choosing MTP® cables, you can choose vendors that provide insertion loss test reports.

(4) Flame Retardant Grade Is Necessary to Consider

The MTP® cable jacket can be made up of different materials, which feature different fire resistances and are suitable for various scenarios. These materials are divided into PE, PVC, LSZH, Plenum, Riser, etc., most of which have good flame retardant properties. If there are higher requirements for the installation environment such as in drop ceiling and raised floors, it is best to choose a high flame retardant level, which is not easy to burn or smoke whenever there is a fire. The table below tells you how to judge the flame retardant grade of various jacket materials and application scenarios.

| MTP®/MPO NEC Rating | Flame Retardant Level | Application Scenarios | Possible Substitute |

|---|---|---|---|

| OFNP | Rank 1 (Highest) | Horizontal wiring area and aerated environment (conveying pipes, air handling systems, etc.) | Can’t be replaced by cables with lower ratings |

| OFNR | Rank 2 (Middle) | Vertical wiring area (connection between entrance equipment or computer room and communication cabinets on different floors) | OFNP |

| OFNG/OFN | Rank 3 (Lower) | Common area | OFNP, OFNR |

When buying MTP® cables, you can directly see the flame retardant grade on the outer jacket, and then choose the best MTP® cable according to the real using environment based on Fiber Optic Cable Jacket & Fire Rating.

(5) Strict Fiber Cable Test Should Be Taken

- Good MTP® Cable Passes End-Face Inspection

To ensure that many fiber-optic connectors have qualified or even high performance, the International Electrotechnical Commission (IEC) created IEC 61300-3-35. This standard specifies the pass/fail requirements for connector end face quality before connection. A connector end face is divided into four zones, namely core, cladding, adhesive and contact. It has requirements for scratches and defects in each zone inside the connection. The scratches represent the permanent linear surface features. The defects include all non-linear features detectable on the fiber, including particulates, other debris, pits, chips, edge chipping, etc. The cleaner the end face is, the better the cable quality is. Therefore, to buy the best MTP® cable, you should choose the one that passes end-face inspection like FS MTP® cables.

| Zones | Scratches | Defects |

|---|---|---|

| A: Core | None | None |

| B: Cladding | No limit ≤3 μm; None >3 μm | No limit 5 μm |

| C: Adhesive | No limit | No limit |

| D: Contact | No limit | None ≥10 μm |

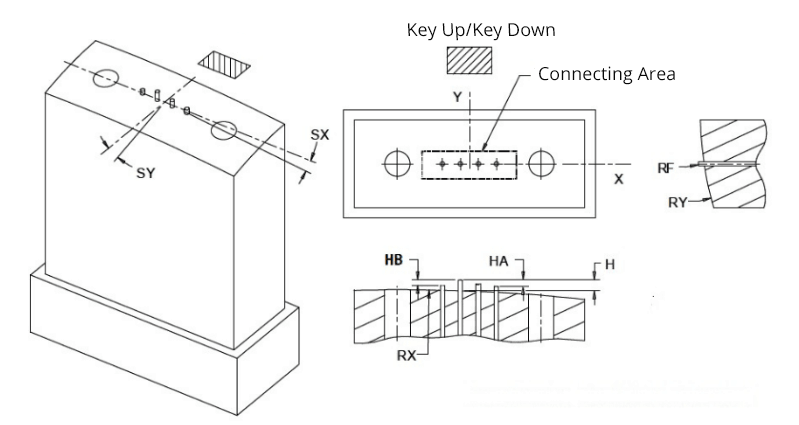

- Good MTP® Cable Passes 3D Interferometer Test

The success of the fiber link connection depends on the quality of the physical fiber optic connection. This physical connection is a function of the geometry of the end face of the connector itself. If this geometry is not strictly controlled, there will not be a long-term reliable connection of the network. The “3D” test specifies technical parameters for the connector as follows:

| Item | Requirements |

|---|---|

| Ferrule X angle (SX) | -0.2~0.2° (PC and APC) |

| Ferrule Y angle (SY) | ±0.2° |

| Ferrule X radius (RX) | ≥2000 mm |

| Ferrule Y radius (RY) | ≥5 mm |

| Fiber Curvature Radius (RF) | ≥1 mm |

| Fiber height (H) | 1000~3000 nm |

| Max fiber height diff (HA) | 500 nm |

| Max adjacent height diff (HB) | 300 nm |

| Coplanarity | ≤2000 nm |

| Core dip | -100nm~+200 nm |

If the geometry cannot meet the requirements, there will be a huge risk of system connection failure. So it is very important to choose the MTP®/MPO cable which passes the 3D Interferometer test.

Advice on Buying MTP® Cable

From all the above, there are many factors we could consider before buying MTP® cables. Nowadays, numerous vendors could offer cables for MTP® connection. However, not all the cables are quality assured. To get the best MTP® cable, choose the one that can meet all the standards mentioned above.For example, Fiber-Life meets all of the above conditions, welcome to buy from sales@fiber-life.com!