Specialty Fiber Cables represent a niche category of optical cables tailored to meet specific environmental, mechanical, or performance demands that exceed those of standard fiber optic cables. These cables are meticulously engineered for applications where durability, precision, and adaptability are paramount. The spectrum of specialty fiber cables encompasses armored cables, fiber loopback cables/modules, industrial cables, and polarization-maintaining (PM) cables. In this blog, we delve into the nuances of these types and their targeted applications.

Armored Cables: Fortification and Durability

Armored fiber cables are crafted to endure harsh environments. They boast an additional protective layer, typically steel or another robust material, which safeguards the delicate fiber core from physical harm. These cables are frequently deployed in outdoor settings, such as subterranean installations or industrial settings where they might be subjected to physical stress, moisture, or chemical exposure.

Key Applications:

- Outdoor environments

- Subterranean cable networks

- Industrial facilities facing harsh conditions

The armoring layer enhances the cables’ resilience without sacrificing flexibility, ensuring a longer service life and reduced maintenance expenses.

Fiber Loopback Cables/Modules: Diagnostic and Testing Tools

Fiber loopback cables and modules are meticulously designed for diagnostic and testing procedures, as well as network setup. They facilitate a loopback signal, which redirects transmitted signals from a device back to its receiver, thereby testing the device’s functionality. They are indispensable in the development, testing, and maintenance of optical network components.

Key Applications:

- Network equipment testing

- Device diagnostics and troubleshooting

- Laboratory environments for system evaluation

Fiber loopbacks are commonly utilized in settings like data centers or labs where equipment must be rigorously tested for accuracy and reliability prior to deployment.

Industrial Cables: Resilience in Challenging Environments

Industrial fiber cables are engineered to perform exceptionally in challenging environments, such as manufacturing facilities, mining operations, or extreme outdoor conditions. These cables are designed to withstand environmental hazards like extreme temperatures, vibrations, and chemical exposure. They often feature robust outer jackets and additional protective layers to ensure optimal performance under less-than-ideal conditions.

Key Applications:

- Manufacturing plants

- Mining and oil industries

- Environments with extreme weather conditions

Industrial cables are typically more resistant to mechanical stress and environmental factors, making them a dependable choice for heavy-duty industries.

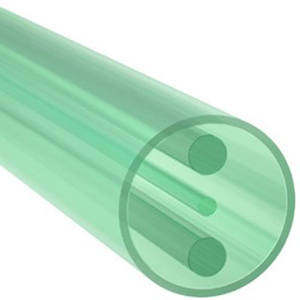

PM Cables: Precision and Stability

Polarization-maintaining (PM) cables are a class of specialty fiber cables designed to preserve the polarization of light as it traverses the cable. These cables are highly precise and are employed in applications where maintaining the state of polarization is critical, such as in advanced telecommunications, laser systems, and sophisticated sensors.

Key Applications:

- Advanced telecommunications

- Laser systems for precision cutting or medical procedures

- Fiber optic sensors for scientific applications

PM cables ensure signal integrity and minimize loss, rendering them indispensable in high-performance optical systems.

Choosing the Right Specialty Fiber Cable

When selecting a specialty fiber cable, it’s crucial to consider the environment in which it will be deployed, the level of durability required, and the performance characteristics necessary for your specific application. Each type of cable is tailored for different conditions and objectives, so understanding your needs is pivotal to making an informed decision.

- For rugged environments: Armored cables are the optimal choice for protection against physical damage.

- For testing and diagnostics: Fiber loopback cables/modules offer an ideal solution for equipment testing.

- For industrial settings: Industrial cables are designed to withstand tough environmental challenges.

- For precision-based applications: PM cables ensure stability in high-performance optical systems.

Conclusion

Specialty fiber cables are vital for a broad array of applications, ranging from industrial environments to high-precision telecommunications. Gaining an understanding of the specific types—such as armored cables, fiber loopback cables/modules, industrial cables, and PM cables—will assist you in selecting the appropriate solution for your project. Whether you’re seeking rugged durability or high-performance precision, specialty fiber cables provide the versatility and reliability you require.