When designing fiber optic networks, the choice of cable jacket is more critical than often realized. This article explores the differences between Low Smoke Zero Halogen (LSZH) and Polyvinyl Chloride (PVC) cables, emphasizing their safety implications and performance characteristics.

The Critical Choice Between LSZH and PVC Cable Jackets

In the rapidly evolving landscape of technology, safety regulations and potential hazards are sometimes overlooked in the pursuit of high-quality products. For IT managers, the safety of network infrastructure is a critical concern, especially in data centers where numerous networking equipment and cables can be vulnerable to fire and other disasters. Adhering to the latest regulations and safety tips is not just a compliance issue but a matter of life safety.

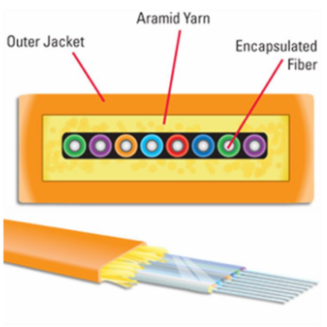

The Importance of Cable Jackets in Network Infrastructure

| Outer Jacket | PVC | LSZH |

| Cost | Lower | Higher |

| Security | Toxic gases produce large amounts of smoke when burned | Low smoke and halogen-free, environmentally friendly and safe |

| High Temperature Resistance | Poor | Better |

| Flexibility | Better | Poor |

| Wear Resistance | Better | Poor |

| Applicable places | Suitable for general environment | Suitable for places with high fire risk, such as tunnels, airports, etc |

The cable jacket plays a pivotal role in network infrastructure, particularly in terms of safety. The European market demands that all cables used in Wide Area Networks (WAN), Local Area Networks (LAN), and Storage Area Networks (SAN) meet the latest IEC 60332-1 standard for Flame Retardant Grade specification. Low Emitting Zero Halogen (LSZH) cables meet these requirements, unlike Polyvinyl Chloride (PVC) cables. Almost every large installation in Europe must comply with this specification, and many are adopting the even more stringent IEC 60332-3 standard for LSZH cables.

Differences in Standards Between Europe and North America

While European standards focus on low-smoke, zero-halogen cables, North American standards emphasize fire resistance and specific electrical performance, particularly wet electrical qualifications. This difference explains the slower adoption of LSZH products in North America.

Quality Testing of Cable Jackets

Cable jacket quality is assessed through various tests, including electrical performance, flame propagation, halogen content measurement, and smoke measurement. The electrical performance test is crucial, distinguishing the insulation material from the jacket material. Long-term insulation testing in water and capacitance and relative permittivity tests are among the most well-known.

Long-Term Insulation Testing in Water

This test measures the resistance of the insulating material over 12 to 36 weeks by immersing the conductor in water at a specific temperature while applying AC voltage. If the resistance does not significantly decrease, the cable is deemed safe for wet and dry applications.

Capacitance and Relative Permittivity Test

This test evaluates the capacitance and permittivity levels of wet-rated conductors, measuring the material’s ability to store electrical energy and charge. Acceptable values for relative permittivity are 6.0 or less, and for capacitance, the value should not increase more than a specified percentage over given intervals.

Flame Propagation and Smoke Measurement Tests

Flame propagation tests assess how cables respond to exposure, while smoke measurement tests evaluate the amount of smoke released. Cables must meet specific limits for char length and smoke release to pass these tests.

Halogen Content Measurement

An X-ray fluorescence test determines halogen content, with LSZH cables passing if they contain less than 0.2% halogens by weight.

Safety and Performance Differences Between PVC and LSZH Cables

The key difference between PVC and LSZH cables is the amount of dangerous, toxic gases emitted in case of fire. LSZH cables emit significantly fewer toxic gases due to their compound composition. While PVC cables meet UL 1581, UL 1666, and UL910 standards, they still release large amounts of toxic gases. LSZH cables are physically distinct, being rougher and more rigid due to their flame-resistant material, and less flexible than PVC cables.

Conclusion

Choosing the right cable jacket is not just about performance but also about safety. LSZH cables, while more expensive, offer significant advantages in terms of reduced toxic gas emissions and compliance with stringent safety standards. For network designers, the decision between LSZH and PVC should be guided by a commitment to safety, environmental responsibility, and long-term reliability. For more information on selecting the optimal cable jacket for your network, contact FiberLife today.