Integrating a building into a fiber or coaxial network is a complex endeavor. Planning such a deployment requires a keen eye for environmental and topographical nuances, a strategic choice of installation methodologies, and the selection of apt equipment.

Implementing the Plan

Executing the plan is akin to embarking on a civil engineering feat, ensuring the cable reaches its destination flawlessly. This might entail repurposing existing ducts or forging new paths within and around buildings.

The Vital Phase: Testing

However, the job is far from over. In fact, the most critical phase—testing—is yet to commence. Testing is not just about verifying the connection’s functionality; it’s about ensuring its reliability, compliance with industry standards, and acceptance by the network owner. This phase is indispensable, regardless of whether it’s mandated.

Testing in Fiber Network Deployments: A Three-Phase Approach

- Visual Inspection

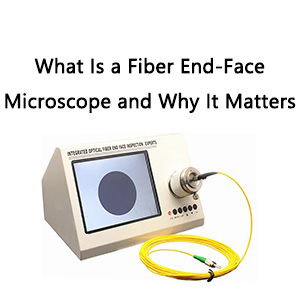

Begin with a thorough on-site inspection of the installation. Scrutinize the cable route, its starting and termination points, pathways, and all equipment rooms. Identify any installation issues, confirm the use of specified materials and equipment, and verify adherence to design specifications and safety codes. Rectify any discrepancies and update the plan accordingly. For fiber optic cables, closely examine the connector end faces, as even microscopic contaminants can severely affect performance. Routinely clean each connector using high-grade, lint-free materials and pure Isopropyl Alcohol (IPA).

Ensure every component is accurately labeled and recorded for future reference, with labels placed securely yet visibly for inspection purposes.

- Technical Testing

With visual verification complete, proceed to assess the network’s performance. The equipment required varies based on the network type. For fiber networks, the key metric is optical loss, or attenuation, as high optical return loss (ORL) can disrupt the laser’s transmission. This is especially critical in wavelength-division multiplexing systems.

It’s prudent to test and document individual component loss readings, such as connectors, cables, and splices, using an Optical Time Domain Reflectometer (OTDR). This practice not only uncovers potential faults that might be overlooked by an OLTS, which measures end-to-end readings, but also identifies specific component issues, facilitating the diagnosis of failures. The TIA/TSB 140 standard mandates testing each fiber link with an Optical Loss Test Set (OLTS) kit. Utilize an optical power meter and a light source to measure loss and verify it’s within acceptable limits. If excessive loss readings are detected, inspect the connectors first, then the cable route. Cables that are bent too tightly can also result in high loss readings.

- Documentation

The final phase of testing is comprehensive documentation. Without records, there’s no evidence that tests were conducted.

Before testing, agree on the documentation format with the customer or adopt their corporate standard to meet all requirements. Ensure documents are clear, detailing what was tested, the methods used, when and where it was done, and by whom. Include adherence to national and international standards, which is crucial for insurance purposes.

Conclusion

The acceleration of FTTH rollouts may increase the pressure to complete deployments swiftly. However, this urgency must not compromise a thorough testing regime. Proper testing is essential to certify the network, record compliance, and preempt potential issues, ensuring the long-term integrity and performance of the fiber network.