Product Introduction

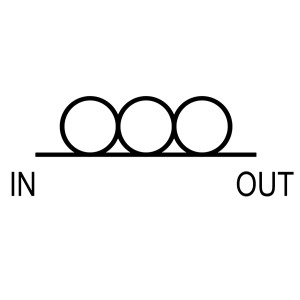

The 3 paddles mechanical fiber polarization controller is a simple fiber polarization controller with low accuracy and easy to use, suitable for 900um fiber. Polarization controllers can be provided without fiber or with 900um fiber coils. The 3 paddles mechanical fiber polarization controller has a wide range of applications in device testing, fiber sensing, and development and research. This product is mass-produced, well-made, and low-cost, making it an ideal choice for users in experimental research.

Working Principle

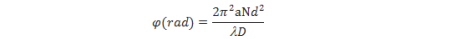

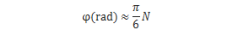

The 3 paddles polarization controller uses stress-induced birefringence to change the polarization of single-mode optical fibers wound on three independent spools to form three independent fiber wave plates. The amount of birefringence generated in the fiber is a function of the fiber cladding diameter, spool diameter, number of fiber loops, and wavelength of light. The required birefringence is caused by the loops in the fiber, not by the twisting of the three fiber paddles. By manually rotating the paddles to twist the fiber, the output fiber polarization vector can be quickly adjusted. In order to achieve the conversion of input polarization state to arbitrary output polarization state, a combination of three paddles (quarter wave plate, half wave plate and quarter wave plate) is used. The phase delay of each paddle can be estimated according to the following formula:

Where j is the phase delay, a is a constant of 0.133, N is the number of fiber turns on the paddle, d is the fiber cladding diameter, l is the operating wavelength, and D is the paddle diameter. For example: when the operating wavelength is 1550nm, the fiber cladding diameter is 125um, and the paddle diameter is 56mm, the relationship between the phase delay of each paddle and the number of fiber turns is:

For example, for a quarter wave plate, when the phase delay is π/2, N=3; For a half wave plate, when the phase delay is π, N=6.