Fiber optic networks are the backbone of modern communication infrastructure, and the success of these networks hinges on two critical components: optical transceivers and Fiber Optic Patch Cords. These seemingly simple components play a crucial role in ensuring seamless data transmission. However, selecting the right patch cords can be a daunting task, especially for those without extensive experience in fiber optics. This guide aims to demystify the process, providing essential tips to help you make informed decisions and avoid potential pitfalls.

Understanding the Basics

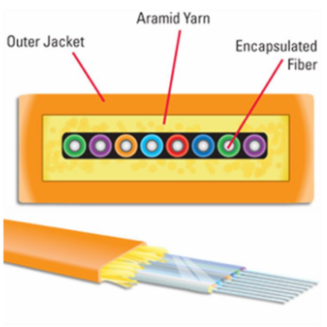

Before diving into the specifics of patch cords, it’s essential to grasp the fundamental concepts of fiber optic networks. The core idea is simple yet ingenious: electrical signals are converted into light and transmitted through ultra-thin glass or plastic fibers. The light travels through the fiber’s core, surrounded by a layer called “cladding” that ensures the light remains within the cable through a phenomenon known as “total internal reflection.” This design allows for high-speed, long-distance data transmission with minimal signal loss.

FiberLife takes this concept to the next level by using advanced, ultra-pure Corning glass for both the core and cladding, ensuring maximum performance and reliability. The cables are further protected by multiple layers, including a durable outer jacket that guards against bending, moisture, and temperature fluctuations.

Types of Fiber Optic Patch Cords

Fiber optic patch cords come in two primary types: Single-Mode Fibers (SMF) and Multi-Mode Fibers (MMF). Each type serves distinct purposes and offers unique advantages.

Single-Mode Fibers (SMF)

-

E2000/APC To E2000/APC Simplex OS2 Singlemode Fiber Patch Cable

Price range: $10.56 through $41.31 -

LC/UPC To LC/UPC Duplex OS2 Singlemode Fiber Patch Cable

Price range: $4.68 through $67.14

SMF cables have a small core that allows only one mode of light to pass through. This design minimizes light reflections, enabling the signal to travel longer distances with higher bandwidth. SMF is ideal for long-haul, high-capacity applications such as data centers and telecommunications infrastructure.

- OS1: Designed for indoor use, OS1 cables are perfect for data centers and other controlled environments.

- OS2: Built for outdoor applications, OS2 cables can withstand harsh conditions, making them suitable for underground or aerial installations.

Multi-Mode Fibers (MMF)

-

Customized OM1 Multimode Duplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $3.70 through $122.00 -

Customized OM1 Multimode Simplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $1.70 through $68.20 -

Customized OM2 Multimode Duplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $3.50 through $124.00 -

Customized OM2 Multimode Simplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $1.60 through $67.30 -

Customized OM3 Multimode Duplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $3.70 through $144.00 -

Customized OM3 Multimode Simplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $1.60 through $77.20 -

Customized OM4 Multimode Duplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $3.30 through $175.00 -

Customized OM4 Multimode Simplex LC/SC/FC/ST Fiber Optic Patch Cable

Price range: $1.80 through $92.20

MMF cables have a larger core diameter, allowing multiple modes of light to travel simultaneously. While this increases signal capacity, it also limits transmission distance due to increased light reflections. MMF is commonly used in local area networks (LANs) and access layers.

- OM1 and OM2: These older generations of MMF cables are suitable for short-distance applications with lower bandwidth requirements.

- OM3 and OM4: These advanced MMF cables support higher data rates and longer distances, making them ideal for modern LANs and data centers.

Choosing the Right Patch Cord

Selecting the correct patch cord involves several critical considerations:

- Transmission Media: Determine whether your application requires single-mode or multi-mode fibers. Single-mode is ideal for long distances and high bandwidth, while multi-mode is better suited for shorter distances with moderate bandwidth needs.

- Data Rate and Distance: Ensure the patch cord supports the required data rate and transmission distance. For example, OM4 cables offer higher bandwidth and longer reach compared to OM1 or OM2.

- Connectors: Fiber optic connectors are precision-engineered components that must align microscopic fibers perfectly. Common connector types include:

- ST (Straight Tip): One of the earliest connectors, featuring a 2.5mm ferrule and a twist-on/off coupling mechanism.

- SC (Subscriber Connector): Developed by NTT, SC connectors feature a 2.5mm ferrule and a push-on/pull-off mechanism.

- LC (Lucent Connector): With a smaller 1.25mm ferrule, LC connectors are ideal for high-density applications.

- MPO/MTP: These connectors bundle multiple fibers into a single ferrule, supporting up to 12 strands. They are perfect for cross-connect and breakout applications.

- Compatibility and Quality: Always choose patch cords from reputable manufacturers like FiberLife, which ensures compatibility with various vendors’ equipment and meets or exceeds industry standards such as Telecordia GR-326 and GR-1435.

Additional Tips

- Seek Expert Advice: Even if you’re experienced, consulting with a knowledgeable colleague or industry expert can provide valuable insights and help you avoid costly mistakes.

- Future-Proofing: Consider future upgrades and scalability when selecting patch cords. Investing in higher-grade cables like OM4 or OS2 can save time and resources in the long run.

- Quality Assurance: Look for certifications and quality assurances like Low Smoke Zero Halogen (LSZH) sheathing, which enhances safety and reliability.

Conclusion

Buying the right fiber optic patch cords is a critical decision that can significantly impact the performance and reliability of your network. By understanding the differences between single-mode and multi-mode fibers, selecting the appropriate connectors, and prioritizing quality and compatibility, you can ensure a seamless and future-proof installation. With FiberLife, you have a reliable partner that offers a wide range of high-performance solutions tailored to meet your specific needs.