Fiber attenuators are essential in fiber optic systems, as they help to manage light intensity by either absorbing or scattering light. This prevents overloading of fiber optic receivers, which can occur if too much light is present.

How Do Fiber Attenuators Work?

Fiber attenuators function by either absorbing light, such as through a neutral density thin film filter, or by scattering it, like an air gap. They should never reflect light, as this could lead to unwanted reflections within the fiber system. Another type of attenuator uses a length of high-loss optical fiber that reduces the input optical signal power to a lower output level. This reduction is achieved through processes such as absorption, reflection, diffusion, scattering, deflection, diffraction, and dispersion.

Key Feature of a Fiber Attenuator

The most important specification of an attenuator is its attenuation versus wavelength curve. Attenuators should uniformly affect all wavelengths used in the fiber system or, at the very least, maintain a flat response. For example, a 3dB attenuator at 1500nm should also reduce the light intensity at 1550nm by 3dB, or as close as possible. This is particularly crucial within a Wavelength Division Multiplexing (WDM) system.

Different Types of Attenuators

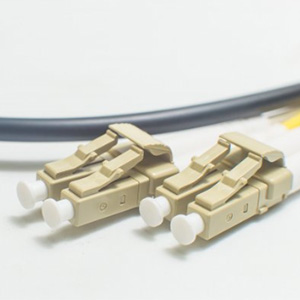

There are two main types of fiber attenuators: plug style (including bulkhead) and inline. Plug-style attenuators function like male-female connectors, with attenuation occurring within the device itself, on the light path from one ferrule to another. Examples include FC, LC, SC, ST, and other types of attenuators. Inline attenuators, on the other hand, are connected to the transmission fiber by splicing their two pigtails.

The operation of attenuators can vary significantly because they use different phenomena to reduce the power of the propagating light. A simple method is to bend the fiber. By coiling a section of cable around a pencil and measuring the attenuation with a power meter, you can create a rudimentary but effective attenuator.

Most attenuators have fixed values, specified in decibels (dB), and are known as fiber optic fixed attenuators. For instance, a -3dB attenuator will reduce the output intensity by 3dB. Manufacturers use various light-absorbing materials to achieve well-controlled and stable attenuation, such as fibers doped with transition metals that absorb light predictably and dissipate the absorbed energy as heat.

Variable optical attenuators are also available and are typically precision instruments used for making measurements. For the best variable attenuators, you can visit Fiber-Life.