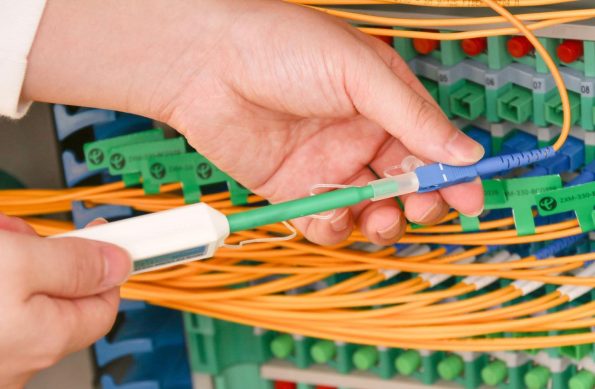

As bandwidth demands grow and data centers become denser, keeping fiber connectors clean is no longer optional—it’s essential. That’s where fiber cleaners come in. From simple one-click tools to professional-grade cleaning pens and cassettes, fiber cleaners ensure your network runs efficiently and reliably.

What Is a Fiber Cleaner?

A fiber cleaner is a specialized tool or consumable designed to remove microscopic dust, oil, and residue from the end faces of fiber optic connectors and adapters. These contaminants may be invisible to the naked eye, but they can cause signal degradation, increased insertion loss, or even physical damage when connectors are mated.

In high-performance fiber optic systems — whether in data centers, telecom networks, or field installations — proper cleaning is a non-negotiable step before mating or testing connectors.

Why Cleaning Fiber Connectors Is So Critical

Fiber cores are incredibly small — typically 9μm for single-mode fibers and 50μm for multimode fibers. Even the tiniest speck of dust can partially or completely block signal transmission. This can lead to:

- High insertion loss: Uncleaned connectors prevent proper light transmission.

- Increased reflectance: Dirty interfaces can reflect the light signal back toward the source.

- Permanent damage: Contaminants can scratch or pit the fiber surface during mating.

- Unstable test results: Testing with dirty connectors leads to false readings and poor-quality assurance.

According to industry studies, over 85% of network failures are caused by dirty connectors — a statistic that underscores the critical importance of using a fiber cleaner as part of any fiber optic maintenance routine.

Types of Fiber Cleaners and How to Use Them

Fiber cleaning tools come in multiple types, each suited to specific connector interfaces and usage scenarios. Here’s how they work and how to use them properly.

1. One-Click Fiber Cleaners

Universal Cleaning Steps

- Remove the protective cap.

- Insert the cleaner into the connector interface (adapter or jumper).

- Gently press until a “click” is heard.

- Remove and inspect if needed.

Models by Connector Type

- 1.25mm (LC/MU): Align vertically for precise cleaning.

- 2.5mm (SC/ST/FC): Ensure ferrule diameter compatibility.

- MPO/MTP Cleaners: Roll wheel backward until two “clicks” are heard; ideal for high-density data centers.

2. Fiber Cleaning Pens

- Select the correct pen type (e.g., KOC-125 for LC/MU, KOC-250 for SC/ST/FC).

- Insert into the connector and press once.

- Repeat 2–3 times if necessary, using controlled pressure to avoid ferrule damage.

3. Fiber Cleaning Cassettes (Cleaning Boxes)

- Hold cassette in one hand, press the release button to expose the cleaning tape.

- Press the connector vertically onto the tape.

- Swipe in a single direction only to avoid secondary contamination.

4. Fiber Cleaning Wipes / Dust-Free Cloths

- Wipe the end face of the fiber in one direction only.

- Use each piece of cloth or paper only once.

- Always wear gloves to avoid recontamination.

Fiber Cleaner Product Comparison Table

| Tool Type | Supported Interfaces | Typical Use Case | Cleaning Cycles | Portability |

|---|---|---|---|---|

| One-Click Cleaner | LC/MU, SC/ST/FC, MPO | Quick field or lab cleaning | 500+ | High |

| Cleaning Pen | LC, SC, MU, FC | Targeted end-face cleaning | 800+ | Medium |

| Cleaning Cassette | Universal (with adapters) | Multi-device or bulk cleaning | 500+ (tape based) | Medium |

| Dust-Free Wipes | All | Emergency or alcohol-free wipe | 1 per wipe | High |

Best Practices for Fiber Cleaning

- Clean Before Every Connection: Always clean before mating or remating connectors.

- Storage Matters: Always use dust caps when not in use.

- Avoid Alcohol: Use ultra-fine dry cleaning methods unless alcohol-based wipes are absolutely necessary.

- No Back-and-Forth Motion: Swipe in one direction only to prevent dragging contaminants.

Why Fiber Cleaners Are Essential

FiberLife Fiber cleaners are more than just accessories—they are essential tools in your fiber optic maintenance toolkit. Regular, proper cleaning ensures maximum performance, lower return loss, and prolonged connector life.

Whether you’re deploying in data centers, telecom rooms, or enterprise networks, having the right cleaning tools—and using them correctly—is the key to a reliable and efficient fiber optic system.