Specialty fiber cables are engineered to meet the specific demands of various industries and environments, ensuring reliable performance under challenging conditions. These cables offer advanced protection and functionality compared to standard fiber optic cables, making them ideal for applications ranging from industrial use to testing environments. Below, we explore the different types of specialty fiber cables, their uses, and why they are crucial in certain settings.

Armored Cables for Enhanced Durability

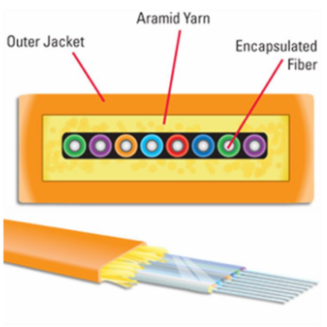

Armored cables are engineered with an additional layer of protection to shield the fiber from harsh conditions, including physical damage, rodents, or extreme environmental factors. These cables are typically used in outdoor installations or environments where the cable may be exposed to tough conditions, such as underground deployments, industrial plants, or construction sites.

The outer layer of these cables is usually made from materials like steel or aluminum, which makes them highly resistant to pressure or cutting. This feature ensures the cable remains intact, even when subjected to intense stress, providing continuous fiber signal transmission without disruptions. Armored cables are essential for ensuring long-term performance and reducing maintenance needs.

Fiber Loopback Cables and Modules for Testing

Fiber loopback cables and modules are critical tools for testing and diagnostics in fiber optic networks. These cables essentially “loop” the signal back to the source, allowing network engineers to evaluate whether the system is functioning correctly. They play a crucial role in identifying and isolating issues in fiber optic networks, ensuring smooth operation and quick repairs when needed.

These loopback cables are widely used during the development phase of fiber systems, helping to ensure that components work as expected before full deployment. They are also used in production environments where equipment testing is required.

Industrial Cables for Harsh Environments

Industrial fiber cables are specifically designed to operate in rugged environments such as manufacturing facilities, oil rigs, and mining operations. These cables are resistant to chemicals, extreme temperatures, moisture, and even mechanical stress. In industries where conditions are extreme, fiber cables must be able to withstand heavy use while maintaining reliable performance.

Industrial fiber cables are built with special jackets and reinforcements to endure such environments without compromising on the quality of the signal. They ensure high-speed data transmission and robust connections in these critical settings, helping maintain network operations even in the harshest conditions.

PM Cables for High-Precision Applications

PM (Polarization Maintaining) cables are specialized fiber cables used in high-precision applications that require maintaining the polarization of light over long distances. These cables are often used in telecommunications, medical equipment, and laser systems where high precision and reliability are necessary.

The key feature of PM cables is their ability to preserve the polarization state of light, which is critical in applications like optical sensing and high-speed data transmission. These cables offer superior performance in environments where maintaining the integrity of light transmission is crucial.

Conclusion

Specialty fiber cables, such as armored cables, fiber loopback cables, industrial cables, and PM cables, are essential components in specific applications where standard fiber cables may not provide the necessary protection or performance. Each type is engineered to meet the demands of particular environments, whether for durability, testing, or high-precision signal transmission.

Choosing the right specialty fiber cable for your needs can greatly enhance the reliability and efficiency of your fiber optic network. Whether it’s protecting your cables from harsh environments, ensuring accurate testing, or maintaining signal integrity, specialty cables provide the solutions required for modern network demands.