Navigating the diverse array of fiber connectors and their specific applications can be quite daunting. This guide aims to demystify the topic by consolidating information from various sources to provide a clear understanding of these essential components.

What is a Fiber Connectors?

A fiber connectors, also known as an optical fiber connectors, is an intricate coupling device that rapidly joins fiber optic cables, facilitating quicker connections and disconnections compared to splicing. It aligns the fiber cores mechanically, ensuring the unimpeded passage of light signals through the cable.

Fiber connectors differ from their electrical counterparts by transmitting light, not electricity, necessitating greater precision. They are characterized by low insertion loss, exceptional insertion repeatability, superior return loss, and a prolonged service life.

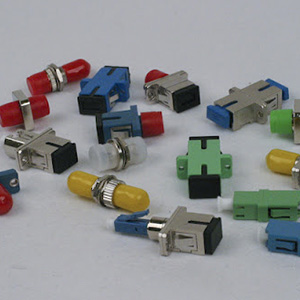

Despite the market introduction of over 100 types, only a select few have gained widespread popularity and usage in the industry. We will now delve into the most prominent types of fiber connectors.

Structure of Fiber Connectors

Before exploring the main types, let’s examine the common structure of fiber connectors. Despite variations, they typically consist of four key components: a ferrule, a connector body, an attachment mechanism, and boots. The following images illustrate the anatomy of a standard SC connector.

SC Connectors

The SC (Standard Connectors or Subscriber Connector) was introduced by NTT in the mid-1980s. This snap-on square connector operates with a simple push-pull motion, akin to everyday audio and video cables. It features a 2.5mm ferrule, which is larger than that of the subsequently developed LC connector.

Initially utilized in Gigabit Ethernet networks, the SC connector gained formal recognition through the TIA-568-A specification in 1991. Its popularity surged as manufacturing costs decreased, and it has been a dominant force in the fiber optic realm for many years. However, its larger size, requiring more space for an equivalent number of ports, has led to a gradual replacement by more compact and modern connectors such as LC and MPO.

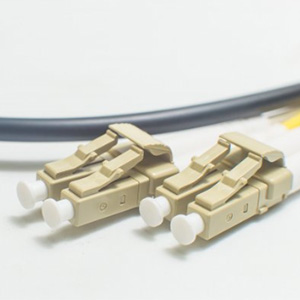

LC Connectors

LC, which stands for “Lucent Connector,” was developed by Lucent Technologies. With a 1.25mm ferrule, half the size of the SC, this compact connector has become extremely popular in data communications, particularly for high-density applications.

The preference for high-efficiency cabling with LC connectors has made them the most frequently used and successful option today. Modern optical transceivers and networking components widely incorporate LC connectors, expanding their deployment and application scope.

FC Connectors

FC, short for “ferrule connector,” was the first to employ a ceramic ferrule. Unlike the plastic-bodied SC and LC, it utilizes a circular screw-type fitting made of nickel-plated or stainless steel. The FC connector’s end face is inserted using an alignment key and then screwed into place with a fiber collet.

Despite the increased complexity in manufacturing and installation, FC connectors remain a viable option for precision instruments such as OTDRs. Their screw-in collet is particularly suited for high-vibration environments, ensuring a secure fit with a spring-loaded collar.

Initially designed for data centers and telecom applications, the FC connector has seen a decline in usage with the emergence of SC and LC connectors, due to higher costs and slower connection speeds.

ST Connectors

Developed and licensed by AT&T shortly after the FC, the ST (Straight Tip) connector features a bayonet mount and a long cylindrical 2.5mm ceramic ferrule to secure the fiber. The spring-loaded ST connector must be properly seated to avoid signal loss, which can be rechecked and reconnected if necessary.

ST connectors are well-suited for both long-distance and short-distance applications, including campus networks, the development of multimode fiber applications, enterprise networks, and military uses.

MPO Connectors

MPO, standing for Multi-fiber Push-On connector, differs from traditional connectors by incorporating a fiber array that supports multiple fibers, up to 12, 24, or even 36 strands.

Due to their complexity, these multi-fiber connectors are not yet field-fit and must be factory-terminated. They are extensively used in high-density data centers or fiber cabling systems that demand space efficiency.

Although the overall cabling cost is higher than that of standard LC, SC, or FC connectors, the MPO connector offers significantly faster deployment and a cost-effective solution on a “per-fiber” basis.

MTP Connectors

The MTP® connector, a registered trademark of US Conec, is an enhanced version of the MPO connector, known for its improved precision, reliability, and superior performance. Naturally, its pricing exceeds that of the standard MPO.

MT-RJ Connectors

The MT-RJ (Mechanical Transfer Registered Jack) is a duplex connector available in both female and male variants, utilizing alignment pins. Though nearly obsolete, specific systems may still require these connectors for maintenance purposes. MT-RJ is exclusively compatible with multimode duplex cables, connecting both fibers through pins and holes, similar to the MPO/MTP connector.

MU Connectors

Developed by NTT, the MU (Miniature Unit Coupling) connector features a 1.25mm zirconia ferrule. It employs a simple push-pull mechanism, a compact design, and a self-holding mechanism, making it ideal for backplane applications.

E2000 Connectors

The E2000 connector, also known as the LSH connector, was developed by Diamond SA. It includes a spring-loaded shutter mechanism that protects the ferrule end face from dust and laser beams. With a one-piece design, it facilitates easy and quick termination and is well-suited for high-safety and power applications.

VSFF Connectors

VSFF, or Very Small Form Factor, represents a new category emerging to meet the demands of hyper-scale and enterprise data centers. According to Corning, VSFF connectors are compact, designed for spaces where fiber network applications are constrained by limited space.

Duplex LC vs. VSFF-connector

The comparison between Duplex LC and VSFF-connectors illustrates the advancements in meeting the needs of 200G/400G/800G data centers. Typical applications include VSFFC transceivers such as QSFP-DD and OSFP, along with VSFFC fiber patch cables and assemblies.

MDC Connectors

The MDC connector, a creation of US Conec, is a Push-Pull-Boot duplex fiber connector that utilizes the industry-standard 1.25mm ferrule while offering three times the density of LC connectors. It is part of the VSFF connectors family, targeting high-density patching applications for SFP-DD, QSFP-DD, OSFP transceivers, and beyond.

CS Connectors

The CS connector is an innovative, high-density, very small form factor (VSFF) fiber optic connector designed for QSFP-DD, OSFP, and COBO transceivers. It achieves a 40% reduction in size and doubles the density of patch panels compared to an LC duplex.

SN Connectors

Developed by SENKO, the SN connector is a new duplex fiber connectors that surpasses the CS connector in density. Utilizing the industry-standard 1.25mm ferrule with a reduced ferrule pitch, it provides a 4x duplex fiber connectors within the same LC size. It is perfect for next-generation hyper-scale data centers, Edge computing, Enterprise, or co-location DCI environments.

Choosing the Right Fiber Connectors

When selecting the appropriate fiber connectors, consider the following steps:

- Fiber Count and Connector Type: Align the connector type with your existing infrastructure and future plans. Opt for the LC connector if using the prevalent SFP module, or MPO/LC for QSFP28 modules. SC and LC are standard choices, with MPO suitable for high-throughput data centers, and VSFF connectors like CS and SN for 400G and above fiber cabling needs.

- Fiber Type: Connectors are categorized into single-mode and multimode types. Single-mode connectors support the longest transmission distances by allowing a single light mode, while multimode connectors, which permit multiple light modes, are cost-effective for shorter distances.

- Polish Type: Be aware of the polish type, as connectors come in PC, UPC, and APC varieties. Each polish type impacts performance and cost, so consult with your supplier before making a selection.