In modern communication systems, the efficient transmission performance of optical fiber is crucial to the speed and stability of the network. The smoothness and precision of the optical fiber end face is one of the key factors to ensure the quality of optical fiber connection. As a specialized technical equipment, the optical fiber polishing machine can effectively improve the quality of the optical fiber end face, reduce the light loss in signal transmission, and thus improve the overall network performance. So, how does the optical fiber polishing machine work? This article will explore in depth the working principle of the optical fiber polishing machine and its application in optical fiber communication.

1.The Core Principle Of Fiber Polishing

Fiber polishing is to achieve precise smoothness of the fiber end face through physical methods. The basic principle is to use special polishing materials and equipment to grind off the rough surface of the fiber end face layer by layer through mechanical means such as rotation, vibration or friction until it reaches the required smoothness.

1.1 The difference between grinding and polishing

Although both fiber polishing and grinding are process steps for processing fiber end faces, their precision and purpose are different. Grinding is used for rough processing, while polishing is the final fine processing to ensure that the fiber end face is scratch-free and burr-free, achieving nanometer-level smoothness.

1.2 Control of polishing angle

The polishing angle of the fiber end face is also very important, especially in APC (angle physical contact) type connectors. The polishing machine ensures that each fiber end face is polished at a specific angle by precisely controlling the polishing angle, thereby reducing light reflection and improving signal transmission efficiency.

2.Composition and workflow of fiber polishing machine

The structure of the fiber polishing machine includes multiple core components, each of which plays a key role in the polishing process.

2.1 Polishing disc

The polishing disc is the component where the fiber end face contacts the polishing material. Polishing sheets of different particle sizes are usually installed on it, and the fiber end face rubs against the surface of the polishing disc when rotating, thereby achieving a polishing effect.

2.2 Fixture

In order to ensure that the fiber remains stable during the polishing process, the fixture can accurately lock the fiber so that it will not deviate or vibrate during the polishing process, thereby ensuring that each fiber end face is evenly polished.

2.3 Polishing fluid

Polishing fluid is used to lubricate and cool the polishing process, and also helps remove tiny debris generated during polishing. The choice of polishing fluid will directly affect the polishing effect and efficiency.

2.4 Automated control system

Modern fiber polishing machines are usually equipped with automated control systems that can automatically complete the entire polishing process according to preset parameters. The control system can adjust the polishing time, pressure, speed, etc. to ensure the consistency of each polishing.

3.Working steps of fiber polishing machine

3.1 Pretreatment

Before polishing begins, the fiber end face needs to be pretreated. The first step is to remove the protective layer of the fiber to expose the fiber core. Then the fiber is installed in a fixed fixture and prepared for polishing.

3.2 Rough polishing

Rough polishing uses a coarser polishing sheet to remove larger uneven parts on the fiber end face. This process usually lasts for a short time, mainly to prepare for the subsequent fine polishing.

3.3 Fine polishing

Fine polishing is the most critical step in the whole process. Using a finer polishing sheet and polishing for a longer time, the fiber end face can achieve a smooth and scratch-free effect. This step determines the optical loss and signal quality of the fiber connection.

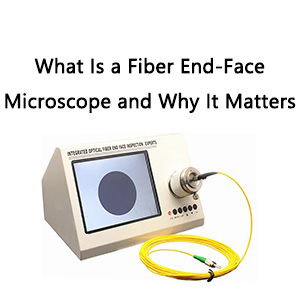

3.4 Cleaning and Inspection

After polishing, the fiber end face needs to be thoroughly cleaned to ensure that there is no residual polishing liquid or tiny debris. Then use the fiber end face detection instrument to check the polishing effect to ensure that the fiber end face meets the expected smoothness and angle requirements.

4. Advantages and Applications of Fiber Polishing Machines

4.1 Advantages

High Efficiency: The fiber polishing machine can complete the polishing of a large number of optical fibers in a short time, greatly improving production efficiency.

Precision: Through automated control, the polishing machine can ensure the accuracy and consistency of each polishing and reduce errors in manual operation.

Flexibility: The polishing machine can be applied to different types of fiber connectors, including SC, FC, LC, etc., with strong adaptability.

4.2 Application Scenarios

Fiber polishing machines are widely used in data centers, fiber to the home (FTTH), telecommunications base stations and other scenarios. In these fields, the transmission performance requirements of optical fibers are extremely high, so the use of polishing machines can significantly improve the quality of optical fiber connections.

5. FAQs

5.1 How long does it usually take to polish a fiber?

The polishing time of the optical fiber depends on the specific equipment settings and the type of optical fiber. Usually, rough polishing takes 1-2 minutes, while fine polishing takes 3-5 minutes.

5.2 What is the impact of polishing angle on signal transmission?

The polishing angle determines the reflection loss of the fiber end face. Especially in the angled physical contact (APC) connector, the precise angle can effectively reduce the reflection of the optical signal and improve the transmission quality.

5.3 Does the polishing machine need regular maintenance?

Yes, the polishing disc, fixing fixture and other parts of the polishing machine need to be regularly inspected and replaced to ensure that the equipment is in the best working condition.

Conclusion

As an important equipment in the processing of optical fiber connectors, the optical fiber polishing machine plays an indispensable role in the field of optical fiber communication with its high efficiency and precision. By understanding its working principle and application, we can better utilize this equipment and improve the transmission performance of optical fiber networks. In the future, with the continuous advancement of optical fiber technology, optical fiber polishing machines will further realize intelligence and automation, providing strong support for the rapid development of global communication networks.