In the rapidly evolving landscape of fiber optic communications, Field Assembly Connectors (FACs) have emerged as a critical component. These connectors are engineered for swift and straightforward installation in the field, eliminating the need for costly or cumbersome equipment. Their primary benefit is the significant time and resource savings they offer, making them an excellent choice for projects where rapid deployment is paramount. This article delves into the role, functionality, and types of Field Assembly Connectors, including FC, LC, and SC Fast Connectors.

The Role of Field Assembly Connectors

Field Assembly Connectors enable rapid fiber optic connections in on-site settings, showcasing their versatility. They are particularly beneficial in scenarios where pre-terminated cables are impractical due to logistical constraints, and where the ability to make real-time adjustments is crucial. FACs streamline the installation process, empowering technicians to achieve dependable, high-quality fiber connections with minimal effort.

By leveraging these connectors, fiber optic systems can be expanded or modified without disrupting existing infrastructure. Whether you’re deploying a network in a data center, extending an FTTH (Fiber to the Home) network, or constructing telecom infrastructure, FACs present a practical solution.

How Field Assembly Connectors Operate

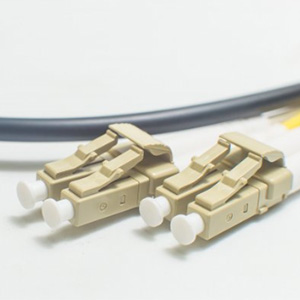

Field Assembly Connectors are designed with user-friendliness in mind. Typically pre-polished and pre-assembled, they require no epoxy, curing, or polishing on-site. A cleaved fiber is inserted into the connector, and the mechanical splice inside ensures a secure connection between the fiber and the connector. This approach minimizes the need for complex fusion splicing and expensive equipment, greatly simplifying installations.

FC, LC, and SC Fast Connectors have become industry standards, offering distinct advantages based on the specific fiber optic application.

Advantages of FC Fast Connectors

FC Fast Connectors are renowned for their robust and reliable design. They are extensively used in telecommunications and data networks, particularly in environments prone to vibration or movement that could compromise connection integrity. FC connectors employ a threaded coupling, ensuring that the connection remains strong and stable, even under challenging conditions.

Use Cases:

- Long-distance communication systems

- High-vibration environments, such as industrial settings

- Telecommunications infrastructure

Benefits of LC Fast Connectors

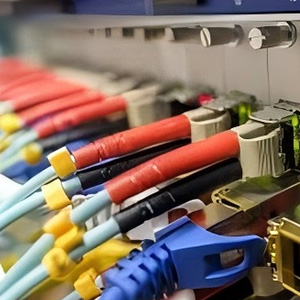

LC Fast Connectors are valued for their compact size and high-density capabilities. They are the preferred choice in data centers and high-density environments where space is a premium. Their compact form factor allows for more connections in a smaller area without compromising performance. LC connectors utilize a push-pull mechanism for easy installation and disconnection, enhancing user-friendliness.

Use Cases:

- Data centers with high-density networking requirements

- FTTH installations

- Telecommunications networks needing multiple fiber connections

Advantages of SC Fast Connectors

SC Fast Connectors provide reliability through their simple push-pull coupling mechanism. They are among the most commonly used connectors in the fiber optic world due to their ease of use and durable design. SC connectors are especially favored in FTTH networks and cable television setups where straightforward and secure connections are essential. The SC Fast Connector facilitates quick installation without sacrificing performance or signal integrity.

Use Cases:

- Fiber to the Home (FTTH) networks

- Cable television and broadband networks

- High-speed Internet service providers

Choosing the Right Connector

Selecting between FC, LC, and SC Fast Connectors largely depends on the specific requirements of your installation. FC connectors are ideal for rugged environments where the connection must withstand physical stress, while LC connectors excel in high-density setups like data centers. SC connectors are best suited for straightforward, large-scale deployments like FTTH.

Additionally, the type of fiber optic cable—whether single-mode or multi-mode—should also guide your decision. Each of these connectors supports both single-mode and multi-mode fibers, but performance and intended use may vary based on project needs.

Conclusion

Field Assembly Connectors, including FC, LC, and SC Fast Connectors, offer a versatile, efficient, and cost-effective solution for fiber optic installations. They enable quick, reliable connections without the need for fusion splicing or epoxy, making them an essential choice for technicians in the field. Whether you’re working on a large-scale FTTH rollout, expanding a data center, or building a telecommunications network, Field Assembly Connectors provide the flexibility and ease that modern fiber optic installations require.