Field Assembly Connectors, commonly known as quick connector, is also generally called field-assembled fiber optic active connector. This type of connector is small in size and fast in termination. The basic termination process only takes 2 minutes and is widely used. It is used in environments such as corridors and household cables, and is therefore widely welcomed by the market. Below, Fiber-Life will briefly introduce fiber optic quick connectors.

Field Assembly Connectors are also called fiber optic field connectors. They are the same product, divided into first, second and third generations, also known as straight-through pre-buried direct melting. Their main differences are:

TOP1:For The Straight-Through Type

It is mainly a dry structure. This structure is very simple, and its advantage is that it is relatively easy to implement and low in cost, but it has many disadvantages: strict requirements on fiber diameter, strict requirements on cutting end face and cutting length, and stricter requirements on supporting strength; otherwise, any mismatch with the product will cause parameter fluctuations; in addition, since the return loss index is completely dependent on the situation of the fiber cutting end face, the return loss index of the product is relatively poor, and the operator’s proficiency is required to be very high. This type of product structure can be used for emergency repair of temporary optical fiber links, but is not suitable for large-scale use of FTTH access links.

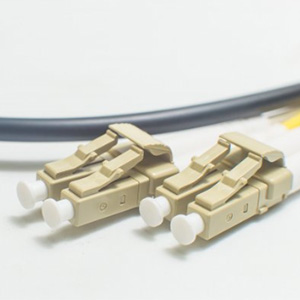

TOP2:For Pre-buried Optical Field Assembly Connectors

It belongs to the pre-buried fiber structure. The pre-buried fiber structure uses a section of bare fiber to be pre-placed in the ceramic ferrule in the factory and the top is ground. The operator only needs to cut the other end of the optical fiber and insert it on site; because the pre-buried fiber in front of the pre-buried structure is ground in the factory and the docking point is filled with matching liquid, it does not rely too much on the flatness of the optical fiber end face cutting, which greatly reduces the requirements for the operator’s proficiency;

because the end face of the connector adopts a pre-grinding process, the return loss index is good; this product structure can achieve better insertion loss (below 0.5dB) and return loss (above 45dB) indicators, and the reliability and stability are relatively high, so it is suitable for use in indoor nodes of FTTH access links.

TOP3:How To Install And Use Optical Field Assembly Connectors?

- Remove the connector tail cover and pass the cable through it;

- Use a fiber optic stripper to strip the cable sheath, the length is about 5CM;

- Place the Miller pliers close to the edge of the fixture to cut off the exposed coating layer to expose the optical fiber;

- Wipe and clean the bare optical fiber with a dustproof cloth;

- Use a fixture to cut the optical fiber;

- Align the optical fiber with the main body hole and insert it. When the optical fiber initially shows a bent state, press the crimping cover down;

- Screw the tail cover on the cable back to the connector body and buckle the shell. The above is the steps for using the optical Field Assembly Connectors. I hope it can help you solve your doubts. The optical Field Assembly Connectors is also called a “live connector”. From this name, we can appreciate its flexible and convenient use.

- Of course, there are many types of optical Field Assembly Connectors, and the materials, performance, stability and service life of different types of optical fiber quick connectors are not the same. Fiber-life will explain more about Field Assembly Connectors in the future. I hope you will continue to pay attention.