High-Quality Fiber Optic Cables: A Necessity for Modern Communications

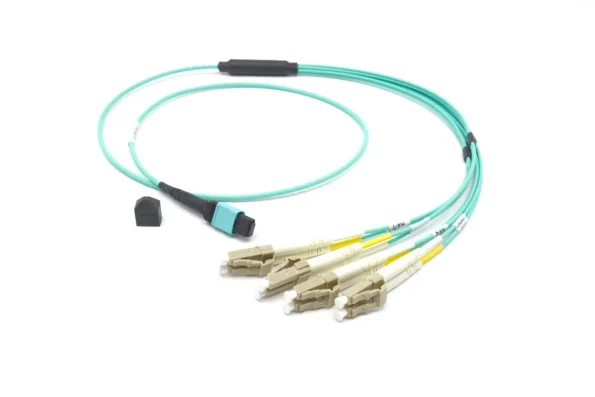

In today’s cutting-edge communications networks, high-quality fiber optic cables are indispensable. MPO-12 breakout cables stand out as a versatile and efficient solution for interconnecting multiple fiber channels in data centers, telecommunications networks, and enterprise IT environments. These cables are renowned for their high-density connections, which not only reduce installation time but also ensure efficient data transmission.

FiberLife: Your Trusted Partner in Fiber Optics

FiberLife is a global leader in the realm of fiber optics, optical networking, and integrated network solutions. We are dedicated to providing high-performance and innovative solutions to a diverse clientele, including individuals, companies, carriers, ISPs, content providers, and network R&D professionals. In this article, FiberLife offers a comprehensive, step-by-step guide to installing MPO-12 breakout cables, ensuring a seamless and reliable setup.

Preparation: The Key to Success

Before diving into the installation process, it’s crucial to gather all the necessary tools and materials. Here’s what you’ll need:

- MPO-12 breakout cables

- Fiber optic connectors (LC/SC/FC/ST)

- Fiber optic cleaver and stripper

- Cleaning tools (isopropyl alcohol, lint-free wipes)

- Fiber optic tester

- Safety gear (gloves, safety glasses)

Adhering to all safety protocols and standards is essential to prevent any damage to the cables or harm to yourself. Adequate preparation ensures a smoother installation process and minimizes the risk of errors.

Installation Steps: Precision and Care

- Inspect the Cables and Connectors: Verify that the MPO-12 breakout cable and connectors are in pristine condition. Look for any visible damage that could compromise performance. Ensure all components meet the specified standards and requirements for your project.

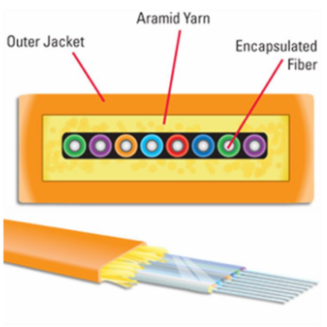

- Prepare the Cable: Carefully strip the outer jacket of the cable to expose the internal fibers using a fiber optic stripper. This delicate step is crucial for maintaining the integrity of the fibers.

- Terminate the Connectors: Attach the connectors to the fiber ends as per the manufacturer’s instructions. Proper termination is critical to avoid significant signal loss.

- Clean the Fiber Ends: Use isopropyl alcohol and lint-free wipes to clean the fiber ends and connectors. This step is vital for removing any dust, oil, or residue that can affect signal quality.

- Splice the Fibers: Follow precise splicing procedures to connect the fibers using a fusion splicer. This ensures a strong, reliable connection with minimal signal degradation.

- Test the Connections: Utilize a fiber optic tester to check each connection. Testing is essential for ensuring each connection meets the required performance standards and helps identify any issues early on.

- Finalize the Installation: Organize and secure the cables within the designated area. Proper cable management is key to maintaining order and facilitating future maintenance.

Important Tips and Tricks

- Handle with Care: Always handle the fibers with extreme care. The glass fibers inside the cables are very delicate and can easily break if mishandled.

- Check Polarity and Alignment: Ensure that the polarity of the connectors matches the requirements of your network setup. Accurate alignment is crucial for maintaining the performance of the connection.

- Regular Cleaning: Clean the connectors and fiber ends regularly to prevent signal degradation. Use isopropyl alcohol and lint-free wipes for cleaning.

- Use High-Quality Tools: Invest in high-quality tools specifically designed for fiber optic cable installation. These tools provide precise cuts and connections, reducing the risk of damage.

Common Issues and Solutions

- Dirty Connectors: Regular cleaning can prevent signal loss. Use isopropyl alcohol and lint-free wipes to clean the connectors before and after installation.

- Mismatched Connectors: Ensure compatibility between the cable and connectors. Using the wrong type of connector can lead to poor performance and signal loss.

- Signal Loss: Use a tester to identify and rectify weak connections. If you notice significant signal loss, check the splices and connectors for any issues.

Conclusion

In conclusion, installing MPO-12 breakout cables demands meticulous preparation, precise execution, and regular maintenance. These steps are essential for a reliable and efficient network setup. At FiberLife, we offer a range of high-quality fiber optic products, including the highly recommended 12 Fibers Singlemode 12 Strands Flat MPO Breakout Cable LC/SC/FC/ST Flat Fiber Cable LSZH/Riser. As a global leader in fiber optic, optical networking, cables, FTTx, fiber cabling, fiber testing, polishing, and comprehensive networking solutions, FiberLife is committed to providing high-performance and innovative solutions.

Whether you are setting up a new network or upgrading an existing one, FiberLife’s products and expertise can help ensure your project is a success. Our commitment to quality and innovation makes us a trusted partner for all your fiber optic needs. Visit our website to learn more about our products and how FiberLife can support your fiber optic network needs.