It is important to know that the MPO/MTP cabling system has been continuously developing and improving since its appearance in 1996. This cabling system is particularly suitable for demanding data center environments, and its design purpose is to meet the specific needs of these high-performance occasions. Here are 10 tips to learn about MTP/MPO Cabling Systems. Let’s take a look!

1. MPO And MTP

MPO is a fiber optic connector – MPO standing for “Multi-fiber Push On” which was originally developed and licensed by NTT Group. Licensing led to several variants of MPO, and MTP®, meaning “Multi-Fiber Termination Push-on” and trademarked by US Conec for their MPO connector, provided some added functionality over MPO in the early years of development. However, over the years the divergence between the two types of connectors has narrowed, with many MPO connectors now offer the same performance and even additional features over MTP.

2. MPO Or MTP Connectors? (SNAP conformance)

MPO and MTP connectors are 100% compatible and interchangeable. MPO and MTP connectors both conform to SNAP (form factor and multiplex push-pull coupling) and are fully compliant with IEC-61754-7 and TIA-604-5 (FOC155).

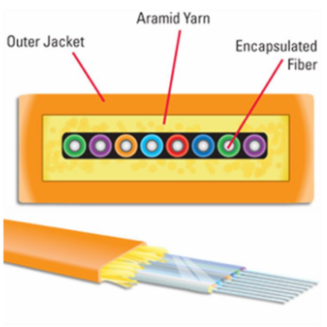

3. What Is An MPO/MTP Cable?

MPO/MTP cables consist of connectors and optical fibers ready to connect and are more flexible and smaller than traditional trunk fiber cables which can often make the data center crowded and difficult to manage. A single MPO/MTP cable can bring together 8, 12, 16, 24 or 32 fibers in one connector, allowing up to 144 fibers in a single 1U chassis using LC connectors. MPO/MTP cables come in multimode, designed for high bandwidth/short range situations, and single mode, which is optimized for data transfer at long range.

4. Connecting Male And Female

MPO cables can have male (two pins) and female (two holes) connectors. To ensure proper alignment connections can only be made between male and female connectors. Adapters are available to convert male to female and vice versa, if needed. One thing to note is that the ports on MPO equipment are usually male, so when connecting to an optical transceiver the MPO trunk cable needs to be female without pins.

5. Color-Coded Cable Jackets

To distinguish between different types of cables, for example, single mode and multimode, and specifications (OS1, OS2 etc), MPO/MTP cable jackets are color-coded. Single mode cables are coded yellow. However, when purchasing single mode, always check the OS specification (OS1 and OS2) to ensure that the correct one is selected. Multimode cables are color-coded in aqua (also representing OM3 and OM4), and lime green for OM5. To avoid confusion between OM3 and OM4, violet colored jackets for OM4 were introduced in Europe by manufacturers and this color has started to be adopted in the USA.

6. Different MPO/MTP Cables

Different MPO/MTP cables are available. Sometimes called “patch” cables, typically used for creating a backbone and horizontal interconnections, have an MPO/MTP connector on both ends and are available from 8 fibers up to 32 in one cable. Breakout cables have MPO/MTP female/male connectors on one end and 4/6/8/12/16 duplex LC/FC/SC/ST connectors on the other. Trunk cables, have the same design as patch cables, but different fiber counts and have multiple “patch” -cables in the same trunk, and are terminated with MPO/MTP connectors on both ends. Trunk cables can be specified for custom demands.

7. More Than Just Cables…

MPO/MTP systems also comprise of different cassettes which we slot into chassis with 4 or 12 slots. The cassettes are available in mini or standard size and typically 8,12 or 24 fibers in 1 cassette. We can have LC or SC connectors on one side and MPO/MTP on the other, or MPO/MTP on both sides. When building with MPO/MTP we can offer a higher density of ports per 1U rack space and it is easier to install than using traditional fiber. An MPO / MTP installation is ready to be installed completely without welding of fiber and all connectors come with measurement protocols so that we know in advance how long links we can connect with the intended equipment. In addition, you can, with simple means, upgrade an installation and grow a solution gradually.

8. Check Which Installation Method You Need

There are three methods for installing cables. The first method polarity A uses straight cable (often referred to as 10G MPO/MTP cable) in a “Key-up to Key-down” position. Straight cable has neutral polarity and is used for extending existing MTP patch and trunk cables. The second method polarity B uses crossover cable (sometimes referred to as 40/100G MPO/MTP cable) that has “flipped” polarity in a “Key-up to Key-up” position. It is not recommended for extending existing patch and trunk cables but can be used to connect directly between a 40/100G optical transceivers. The third method polarity C which is less common, uses pairwise flip cable and is used for maintaining duplex integrity while still using standard cassettes. It is not recommended for extending existing patch and trunk cables but can be used to connect directly between a 40G optical transceivers. The third method which is less common, uses pairwise flip cable and is used for maintaining duplex integrity while still using standard cassettes.

9. MPO/MTP Cleaning

Once installed (as well as during installation and upgrades), maintenance and cleaning is of the utmost importance to ensure that dirt and dust do not contaminate the MPO/MTP connectors as this could affect transmission quality and potentially lead to network failure. Along with dry wipes, pen and cassette tools (such as Senko Smart Cleaner MPO and Smart Cleaner Cassettes) are available to ensure that dust, oil and other debris is removed from the connector without nicking or scratching the end face.

10. Key MPO Benefits

MPO/MTP solutions are ideal for high performance networks where higher data rates are needed. With MPO/MTP cabling data centers can achieve high-density fiber and enable higher speeds without dealing with the risk and complexity of welding on-site. MPO/MTP solutions require considerably less cabling, which in turn makes it easier to handle cables for racks and speed up installation, but also ensures there are less cables to interfere with cooling. As a modular system, it is also much quicker and easier to expand capacity as data center requirements change. The simplicity will definitely save you money in the long run.If you are interested in purchasing MPO/MTP cables, please sales@fiber-life.com contact us!