Optical splitters play an indispensable role in fiber optic networks, serving as coupling devices that facilitate the distribution of signals from multiple sources to various destinations. The commonly referenced MxN configuration illustrates an optical splitter’s capacity to manage M input terminals and distribute signals to N output terminals.

When a single-mode fiber transmits optical signals, not all light energy is confined to the core of the fiber. A portion of it is also transmitted through the cladding near the fiber core. Generally, if the cores of two fibers are sufficiently close, the mode field of the light launched into one fiber can enter the other fiber, leading to a redistribution of the optical signal between the two fibers.

Currently, two principal types of optical splitters have emerged to address the challenges of optical signal distribution: the Planar Lightwave Circuit (PLC) splitter, which leverages optical integration technology, and the Fiber Biconical Tape (FBT) splitter, which is crafted using traditional fiber optic splicing techniques. Manufacturers utilize a conventional Fiber Biconical Tape process for these devices. Both types offer distinct advantages, allowing customers to make an informed choice based on diverse applications and requirements.

PLC Optical Splitter

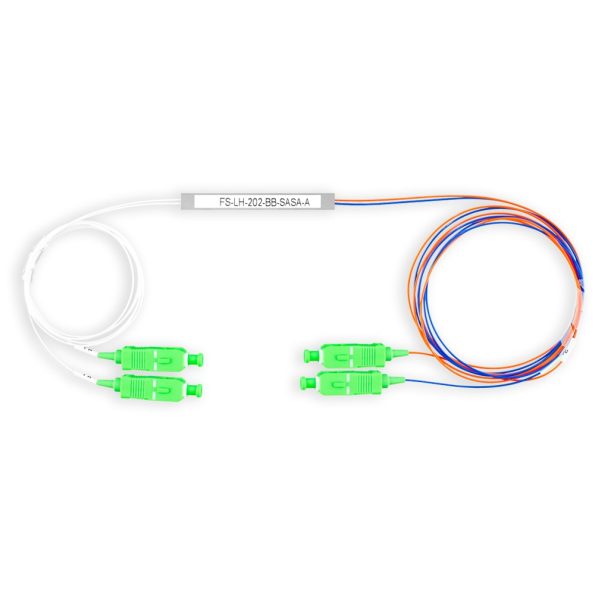

Planar Lightwave Circuit technology harnesses semiconductor innovation to fabricate devices that effectively manage the distribution of optical signals. The splitting is accomplished on a chip, with the capability to achieve up to 1×32 splits on a single chip. The input and output multi-channel fiber ribbons are then coupled at both ends of the chip.

One of the key advantages of the PLC splitter is its insensitivity to the frequency of the transmitted light, meeting the transmission needs of various frequencies. The light is evenly distributed, ensuring that signals are uniformly disseminated to clients. It features a compact design and small size, allowing for direct installation in existing various distribution boxes without requiring significant installation space. A single device can support numerous split channels, exceeding 32 channels, making the multi-channel cost of PLC splitters relatively low.

FBT Splitter

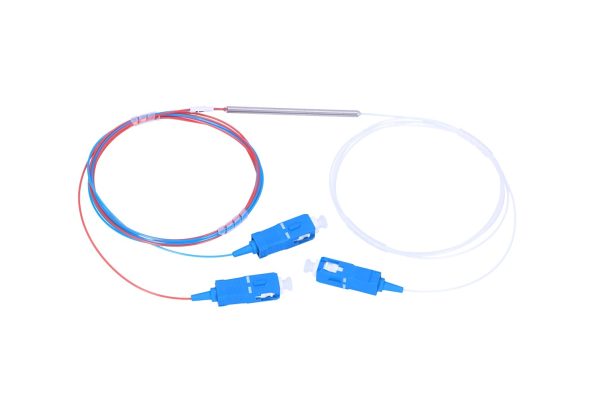

Fiber Biconical Tape technology involves packaging at least two optical fibers together, then fusing and stretching them on a tensioning machine while monitoring the variation in the splitting ratio continuously. Once the splitting ratio meets the requirements, the softening and stretching process concludes. One end retains a single fiber (with the rest cut off) as the input, while the other end serves multiple outputs.

The FBT splitter boasts fundamental benefits stemming from over two decades of development and expertise. It allows for the use of various equipment and processes, with production costs being a fraction of those for PLC splitters. The splitting ratio can be adjusted as needed, enabling the creation of custom splitters.

However, a significant drawback of the FBT splitter is its sensitivity to the frequency of light, which is a critical limitation in applications such as triple-play services, where the optical signals transmitted include frequencies of 1310nm, 1490nm, and 1550nm. The light uniformity of the FBT splitter is poor, with the nominal maximum variation of 1×4 being around 1.5dB, and the variation for higher splits, such as 1×8, is even greater, which cannot ensure uniform light distribution and may affect overall transmission quality. The insertion loss of the FBT splitter is also highly dependent on temperature. For configurations like 1×16 or 1×32, the splitter is typically larger, which can reduce reliability and limit installation space.

Both the PLC and FBT splitters have their own merits in terms of performance and cost, and both technologies are continuously being improved to overcome their respective shortcomings. The FBT splitter is addressing issues of limited form factor and poor consistency, while PLC splitters are also making persistent efforts to reduce costs. Currently, the cost of both devices above 1×8 is nearly identical. As the number of split channels increases, the cost-effectiveness of planar waveguide splitters becomes more apparent.

The optimal selection between these two splitter types hinges on the specific application requirements and customer needs. In certain applications where volume and light frequency are not highly sensitive, especially when there are few branches, choosing an FBT splitter may be more cost-effective. For free information transmission, a 1310nm FBT splitter is utilized. Television video distribution may opt for a 1550nm FBT splitter. For applications requiring multiple frequencies of optical transmission and serving numerous clients, such as triple-play, FTTH, and others, a PLC splitter should be selected.