PM Maintining Cables are specialized cables designed to preserve the polarization of light as it traverses the fiber. This feature is vital for applications where the state of polarization must be meticulously maintained, such as in certain telecommunications and sensing systems. In this article, we delve into the intricacies of PM cables, discussing their design, applications, selection criteria, and usage.

Understanding PM Maintining Cables

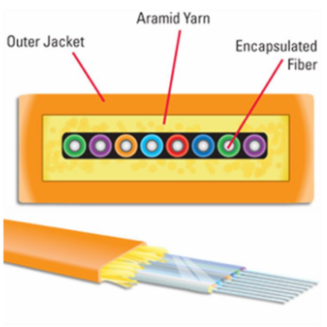

PM fiber optic cables boast a distinctive design that includes a specialized core structure, which minimizes the influence of external factors that could disrupt the polarization of light. They are primarily divided into two categories: PM fibers and PM Maintining Cables. PM fibers are engineered to maintain polarization over extended distances, while PM Maintining Cables facilitate interconnections within systems.

Key Applications

PM Maintining Cables find extensive use in applications such as:

- Optical Sensors: In systems that depend on precise measurements, like strain or temperature sensors, preserving polarization is essential for obtaining accurate readings.

- Telecommunications: In sophisticated communication systems, PM cables enhance the performance of fiber optic components, including amplifiers and interferometers.

Choosing the Right PM Maintining Cables

When selecting PM Maintining Cables, consider the following factors:

- Cable Type: Decide whether you require PM Maintining Cables or PM patch cables based on your specific application needs.

- Core Size: Different applications may necessitate different core sizes. Ensure that the selected cable aligns with the specifications of your system.

- Environmental Conditions: Take into account the installation environment. For outdoor applications, opt for cables that offer superior durability and protection against environmental elements.

Using PM Maintining Cables

Effective use of PM Maintining Cables involves these steps:

- Prepare the Cables: Ensure that the cable ends are clean and free from dust or debris to promote optimal signal transmission.

- Connect to the System: Insert the PM cables into the appropriate ports of your equipment, aligning the polarization direction with the system’s requirements.

- Test the Connections: Post-installation, use optical testing equipment to verify the integrity and performance of the connections.

Conclusion

PM Maintining Cabless are indispensable in applications that demand precise control over light polarization. By grasping their unique characteristics and carefully choosing the right type for your specific needs, you can ensure superior performance in your fiber optic systems. Proper installation and use further bolster the reliability and precision of your applications, underscoring the importance of PM cables in contemporary optical technologies.