In the rapidly evolving digital landscape of today, the necessity for a dependable and efficient network infrastructure has never been more critical. At FiberLife, our mission is to deliver unparalleled value to our global customers in the fiber optic communication field by offering top-notch products and outstanding service. We understand the imperative of upholding a seamless network operation, all the while respecting your budgetary constraints and honoring the value of your time. That’s why we’re excited to introduce you to the revolutionary pre terminated fiber optic cable. These innovative cables are designed for hassle-free installation, saving you both time and money. But what exactly are pre terminated fiber optic cables, and why are they rapidly becoming the preferred choice for businesses and tech enthusiasts alike? Allow FiberLife to enlighten you.

I. Understanding Pre Terminated Fiber Optic Cables: Definition and Working Principle

- Definition of Pre Terminated Fiber Optic Cable

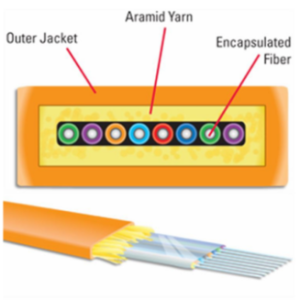

A pre terminated fiber optic cable is a fiber optic cable that has been pre-terminated with connectors in a factory-controlled environment. This means that the tedious and complex process of attaching connectors to the fiber optic cable is done before the cable even reaches the installation site. The outcome is a user-friendly, plug-and-play solution that demands only a basic level of technical know-how for deployment.

- How Pre Terminated Fiber Optic Cables Work

The working principle is straightforward. The factory termination process ensures that each connector is perfectly aligned and tested for performance, reducing the likelihood of errors during installation. The cables are shipped with protective covers on the connectors to prevent damage during transit. Once on-site, installers simply remove the protective covers and connect the cables to their designated ports.

II. Simplified Installation Process of Pre Terminated Fiber Optic Cables

- Eliminating Complex Installation Steps

The defining characteristic of pre terminated fiber optic cables lies in the simplicity of their installation process. Traditional fiber optic cable installation involves a series of steps that require specialized tools and skills. Installers must cut the cable to length, strip the protective coatings, carefully align the fibers, attach connectors, and test the connections. This process is not only time-consuming but also prone to errors.

- Advantages of Plug-and-Play Installation

Conversely, pre terminated fiber optic cables streamline the process by eliminating numerous cumbersome steps. The cables come with connectors already attached, so installers only need to run the cable from one point to another and plug it in. This plug-and-play approach drastically simplifies the installation process. Even technicians with limited fiber optic experience can quickly and efficiently set up these cables, reducing the need for highly specialized labor.

III. Significant Time Savings with Pre Terminated Fiber Optic Cables

- Faster Network Deployment

One of the most significant benefits of using pre terminated fiber optic cables is the time saved during installation. Traditional fiber optic installations can take hours or even days, depending on the complexity and scale of the project. Pre terminated cables, however, can be installed in a fraction of the time.

- Reducing Business Downtime

For example, within a sprawling data center tasked with establishing hundreds or thousands of connections, the time savings afforded by pre terminated cables can be monumental. What would normally take a week with traditional methods might be completed in just a couple of days with pre terminated cables. This not only accelerates the deployment of the network but also minimizes downtime and disruption to the business.

IV. Cost Benefits of Using Pre Termined Fiber Optic Cables

- Lowering Labor Costs

The reduction in installation duration also paves the way for substantial financial savings. Labor costs are one of the biggest expenses in network installation projects. By simplifying the installation process and reducing the time required, pre terminated fiber optic cables lower these costs considerably.

- Decreasing Installation Errors

Additionally, the pre-termination process in a controlled factory environment ensures higher quality and consistency. This reduces the risk of installation errors, which can be costly to troubleshoot and fix. Over time, the reliability of pre terminated cables translates to fewer maintenance issues and lower overall operational costs.

V. Enhancing Network Reliability and Performance with Pre Terminated Fiber Optic Cables

- High-Quality Manufacturing Standards

Rigorous quality control stands as an essential pillar in the manufacturing process of pre terminated fiber optic cables. In the factory, each connector is meticulously attached and tested to ensure optimal performance. This level of quality control is difficult to achieve in the field, where conditions can be less than ideal.

- Ensuring Stable Signal Transmission

This culminates in a connection that is more robust and delivers superior performance. Factory-terminated connectors are less likely to suffer from issues such as signal loss or poor alignment, which can plague field-terminated connectors. The end result is a network that performs better and is more reliable, providing consistent high-speed data transmission.

VI. Diverse Application Scenarios for Pre Terminated Fiber Optic Cables

The versatility of pre terminated fiber optic cables positions them for deployment across a diverse array of applications. Here are a few scenarios where they shine:

- Use in Data Centers

Data centers require high-density cabling solutions to manage the vast amounts of data flowing through their networks. Pre terminated cables are ideal for this environment because they can be quickly deployed and easily managed. Their reliability ensures that data center operations run smoothly, with minimal downtime.

- Application in Enterprise Networks

In corporate settings, network requirements can change rapidly as businesses grow and evolve. Pre terminated fiber optic cables allow for quick and easy network expansions and modifications. Whether it’s adding new workstations, setting up conference rooms, or expanding to new office spaces, these cables provide the flexibility needed to adapt to changing needs.

- Suitability for Outdoor Environments

Pre terminated cables are also well-suited for outdoor installations. Their robust construction and pre-attached connectors mean they can withstand harsh environmental conditions. Whether for temporary events, emergency communication setups, or permanent outdoor networks, pre terminated cables provide a reliable solution that can be deployed quickly.

VII. Conclusion

As technology continues to advance and the demand for high-speed, reliable networks grows, the adoption of pre terminated fiber optic cables is set to increase. By choosing high-quality products from reputable fiber optic cable manufacturers, you can ensure that your network infrastructure is built to meet today’s needs and tomorrow’s challenges.

To fully harness the benefits of pre terminated fiber optic cables, we wholeheartedly endorse the Customized 4 Fiber Pulling Eye Patch Cable Pre-Terminated Singlemode Fiber Optic Cable. This meticulously engineered product from a top fiber optic cable manufacturer delivers unparalleled performance and ease of installation, making it ideal for various network setups, from data centers to enterprise networks and outdoor environments. Embrace the plug-and-play revolution with this cable and enjoy streamlined installation, reduced costs, and enhanced network performance. Visit FiberLife today to learn more about this innovative product and explore our extensive range of fiber optic solutions. Let us help you build a robust and future-proof network infrastructure.

Lanshack offers a vast selection of Cat 5e Patch Cables, Cat 6 Patch Cables, Fiber Optic Patch Cables, Cat 6A Patch Cables and Networking IT Cables & Toolkits.

Hi Lanshack, thanks your comment, FiberLife is so expected to cooperate with your team in fiber patch cable and network cable tools.

Lanshack offers a vast selection of Cat 5e Patch Cables, Cat 6 Patch Cables, Fiber Optic Patch Cables, Cat 6A Patch Cables and Networking IT Cables & Toolkits.