What is polarization-maintaining (PM) fiber?

In theory, optical fibers with round cores should not produce birefringence, and the polarization state of the fiber will not change during propagation. However, in practice, during the production process of conventional optical fibers, they will be affected by external forces, etc., which will cause uneven thickness or bending of the optical fiber, which will cause birefringence. When the optical fiber is affected by any external interference, such as wavelength, curvature, temperature and other factors, the polarization state of light will become chaotic when transmitted in conventional optical fibers.

The application of polarization-maintaining fiber can solve this problem of polarization state change, but it does not eliminate the birefringence phenomenon in the optical fiber, but produces stronger birefringence through the design of the optical fiber geometry, so as to eliminate the influence of stress on the polarization state of the incident light.

How does polarization-maintaining fiber affect the birefringence effect in the optical fiber? During the drawing process of polarization-maintaining fiber, when linearly polarized light is transmitted along one characteristic axis of the optical fiber, part of the light signal will be coupled into another characteristic axis perpendicular to it, which will eventually cause the polarization extinction ratio of the outgoing polarized light signal to decrease, thereby affecting the birefringence effect.

How to make polarization-maintaining fiber?

A commonly used method to introduce high birefringence is to introduce geometrically symmetrical non-uniform stress in the fiber core of the preform rod, by adding two stress rods with improved glass components on both sides of the core. Stress-type polarization-maintaining fiber mainly relies on the difference in thermal expansion coefficients between the embedded stress rods and the fiber core to generate thermal stress, which causes the refractive index of the material to change under the action of thermal stress, thereby producing a birefringence effect. Another option is to use an elliptical core. The elliptical shape itself will produce a certain degree of shape birefringence even without mechanical stress.

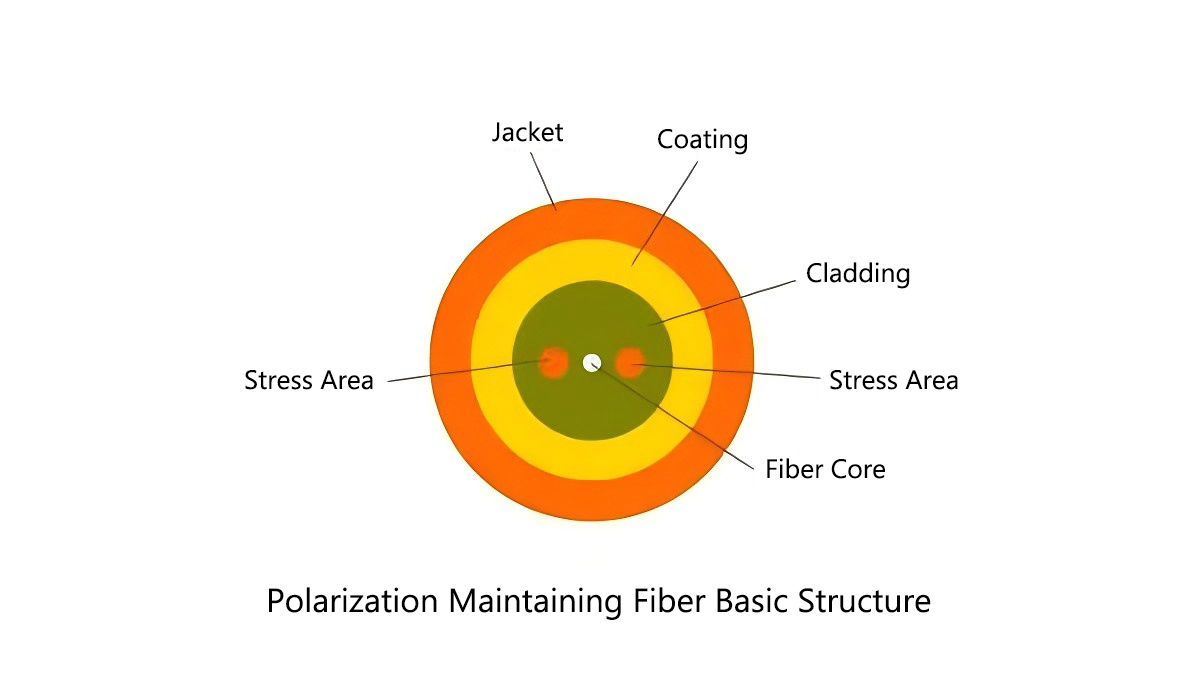

Structure of polarization-maintaining fiber

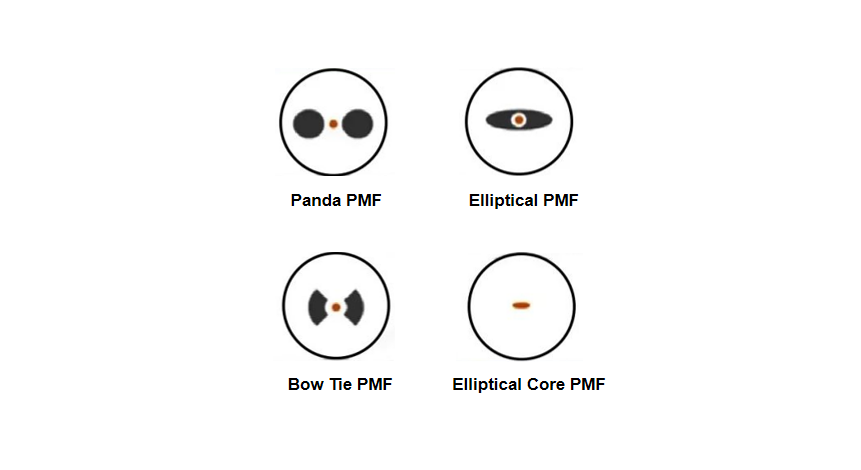

Stressed Polarization Maintaining Fibers mainly include panda, ellipse, bow tie, and ellipse core PMF. Their pros and cons are:

(1) Panda PMF: The size of the preform is large and suitable for mass production. But the area of the stress zone is large and sensitive to temperature.

(2) Elliptical PMF: Good stability. But the size of the preform is small, the stress is concentrated at the top of the stress zone, and the cutting is easy to crack.

(3) Bow Tie PMF: High birefringence. However, it is difficult to control the geometry of the fiber core and the size of the preform is small.

(4) Elliptical Core PMF: Insensitive to temperature, easy to grind the cross-section. But weak birefringence.

What are fast axis and slow axis of polarization-maintaining fiber?

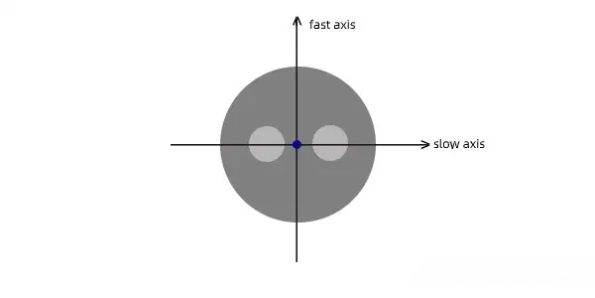

Polarization-maintaining fiber works by causing a difference in the speed of light in two perpendicular polarizations passing through the fiber. This birefringence produces two main transmission axes in the fiber, which are called the fast axis and slow axis of the fiber. The fast axis is an optical axis with a smaller refractive index and a faster light transmission speed, which passes perpendicularly through the midpoint of the line connecting the centers of the two stress zones; the slow axis is an optical axis that passes through the end points of the two stress zones, which is a direction with a larger refractive index and a slower transmission speed.

What is the beat length of polarization-maintaining fiber?

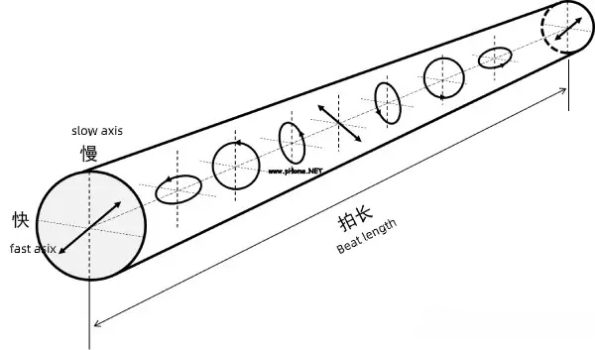

If the polarization direction of the incident linear polarization light is consistent with the fast axis or slow axis of the fiber, the polarization state of the light remains unchanged during transmission. If the polarization direction of the incident light forms an angle with the fast axis or slow axis, two orthogonal polarization modes with different propagation constants will be excited at the same time, and the periodic exchange of power between the two polarization components is called the beat length. Beat length is a very objective parameter of the degree of birefringence of optical fiber. It has nothing to do with the length of optical fiber, polarization and alignment of input light, etc. It can well reflect the periodic change of polarization state of optical fiber. Periodicity refers to the process of polarization state from linear polarization → elliptical polarization → circular polarization → elliptical polarization → linear polarization → elliptical polarization → circular polarization → elliptical polarization → linear polarization along the length of optical fiber, and returns to the original linear polarization state after an integer number of beat lengths.

The formula of beat length is Lp=λ/B, λ is wavelength, and B is birefringence. The smaller the beat length, the greater the difference in light speed between the fast and slow axes, and the stronger the birefringence performance. Typical B value: B=10(-7) for ordinary optical fiber, B=10(-4) for polarization-maintaining optical fiber

What is extinction ratio of polarization-maintaining fiber?

How does polarization-maintaining optical fiber realize the principle of polarization maintenance? When the polarization direction of polarized light is aligned with one axis, the polarization component allocated to the other axis will be very small, thereby maintaining the polarization state of the transmitted light. At this time, the extinction ratio (ER) parameter is introduced to reflect the degree of polarization state maintenance of optical fiber. When the polarization direction of polarized light is aligned with one of the fast and slow axes, two orthogonal polarization modes are generated through the components. The ratio of the polarization component along the original axial direction to the polarization component in the vertical direction is the extinction ratio. The extinction ratio is an important parameter to measure the quality of the polarizer. The larger the extinction ratio, the higher the quality of the polarizer.

ER = 10 log(Pmax/Pmin)